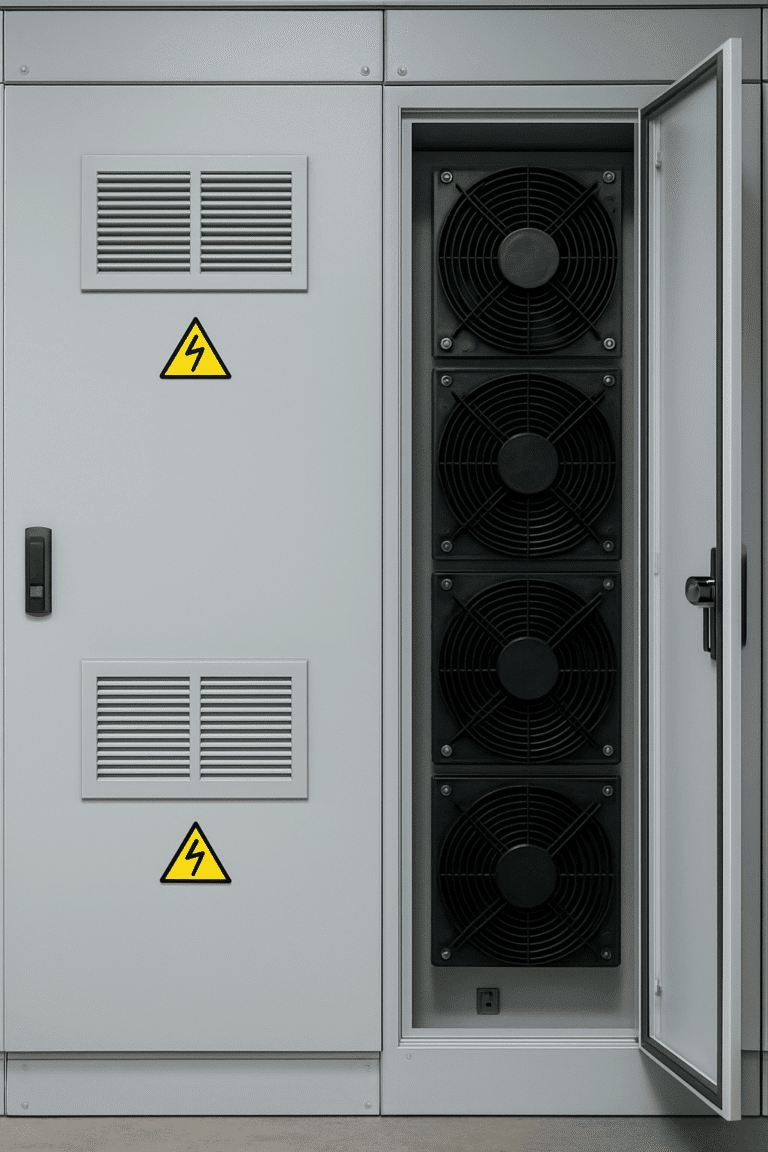

Many industries utilize Leipole fan filter units to maintain stable operation of critical equipment:

🏭 Industrial Automation

In use, they can provide high-grade heat dissipation solutions for PLC control cabinets and frequency converter cabinets, effectively lowering system failure rates due to factor overheating.

🚊 Rail Transit

Satisfying this high reliability and long-life requirement for signaling equipment and onboard control systems, for the stable operation of the system.

⚡ Renewable Energy Industry

Applicable to heat dissipation of photovoltaic inverters, energy storage system battery cabinets, wind power control equipment, etc.

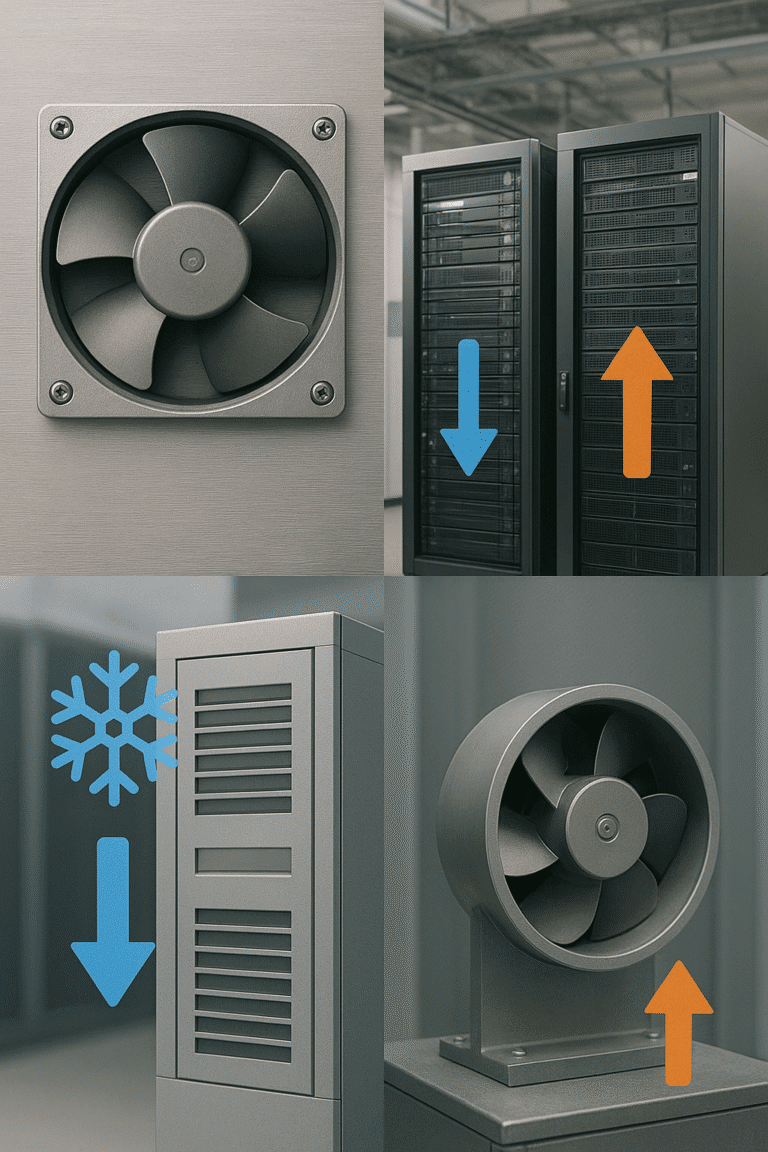

🏢 Data CentersFocusing on heat dissipation solutions for server cabinets and network equipment to help improve operational stability.💡 Smart ManufacturingThe environmental temperature in the electrical cabinet of robotic control systems and production lines, ensuring accurate control during equipment operation.