DIN-Rail Mount Benefits: Snap-in installation speeds up assembly and simplifies service without opening the panel.

1. Core & Lamination Secrets

High-quality control transformers use cold-rolled grain-oriented silicon steel laminations to minimize hysteresis losses. Budget units often skimp on lamination thickness, increasing no-load losses and heat build-up. Look for ones rated with Class B or F insulation that specify maximum temperature rise (e.g., 80 °C) under continuous duty.

2. Inrush Current & Overload Tolerance

A true control transformer design incorporates a dual-tapped primary or soft-start winding to limit magnetizing inrush. Without it, breakers nuisance-trip at power-up. Also, the transformer’s VA rating should include a 115 % continuous overload margin to handle short control-relay pick-up currents without overheating.

3. Isolation vs. Control Characteristics

Unlike isolation transformers, control transformers are optimized for low-voltage control circuits, not for “clean” power. They tolerate DC offsets and low-frequency fluctuations better and often include built-in electrostatic shields between windings to reduce EMI transmitted into PLCs and sensitive electronics.

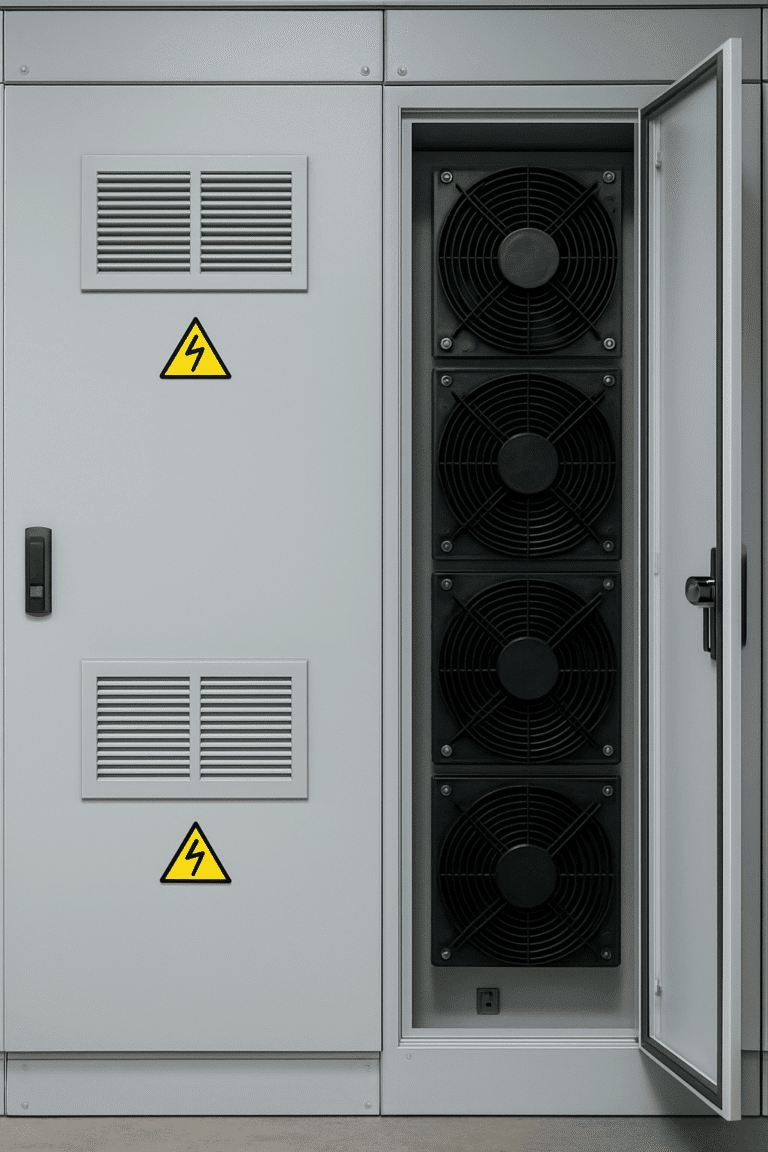

4. Mounting & Vibration Hardening

Industrial panels mounted on mobile platforms (cranes, vehicles) demand anti-vibration bushings on transformer feet. Rigid mounting causes core-coil fatigue under harmonic loads, leading to buzzing and eventual failure. Spring-isolated brackets extend service life in high-vibration settings.

5. Environmental Durability

In dusty or corrosive environments, specify sealed-frame transformers with Class 1 enamel coatings on windings. In tropical climates, look for conformally coated coils rated for 95 % relative humidity—standard coils can suffer insulation breakdown in under two years.

6. Vector Group & Phase Considerations

For three-phase control transformers, vector group (“Y–Δ,” “Δ–Y”) selection affects ground-fault detection and available neutral. A “Δ–Y” unit provides a neutral for control circuits, but introduces a 30° phase shift—critical when syncing with upstream protective relays.

7. Maintenance & Lifecycle Insights

Unlike mains transformers, control transformers run hot and switch loads frequently. Periodic infrared thermography catches hot-spot winding issues early. Investing in a spare coil form—rather than a whole new unit—can halve repair turnaround when field-wound units require rewind.

Delivery delays – affecting project progress and production line stability

Delivery delays – affecting project progress and production line stability