Global layout, zero delivery delays

Global layout, zero delivery delays

-

R&D and sales headquarter led by the team in Singapore – cutting-edge cooling technology iteration to ensure product leadership

-

Manufacturing base in Shanghai, China – ISO 9001 & ISO14001 certified, cost optimization + high quality control standards

-

Localized warehousing in 24 countries – spot shipments from the EU, America, and Southeast Asia, urgent orders arrive within 3 days

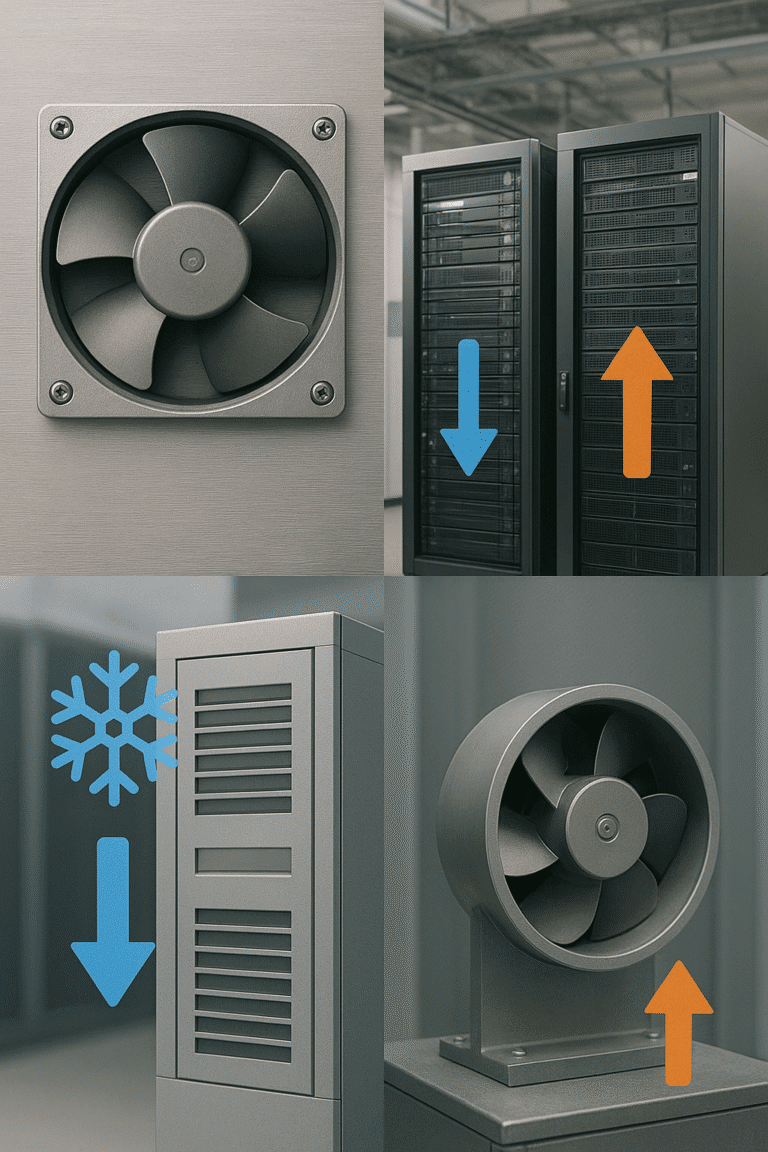

Deep customization capabilities to solve complex needs

Deep customization capabilities to solve complex needs

-

OEM/ODM full-case support – from cooling structure design to branding customization, 100+ successful cases (Industrial Automation/ New Energy Industry/Data Centers)

-

Working condition simulation test – Free simulation of air volume, high temperature, high humidity and vibration environment to ensure 100% adaptability of the solution

Worry-free compliance, global access

Worry-free compliance, global access

-

Authoritative certification – CE, UL, RoHS, REACH full coverage, hassel-free customs clearance in Europe, America and Southeast Asia

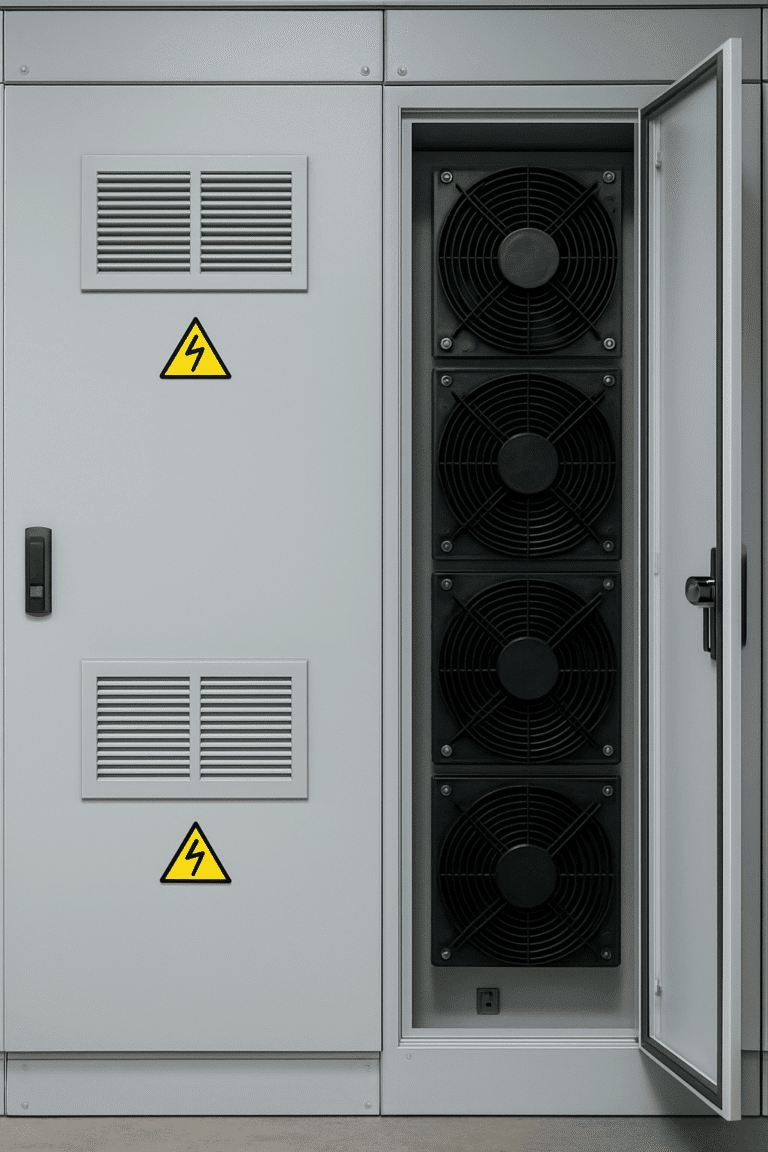

Cost optimization throughout the entire life cycle

Cost optimization throughout the entire life cycle

-

Energy consumption reduced by 30% – patented airflow design, saving 30% in electricity bills per year compared to peer product

-

1-year warranty – redundant design of key components, failure rate <0.2%

-

7×24 localized service – 50+ national technical teams, 4-hour response, direct supply of spare parts.

Delivery delays – affecting project progress and production line stability

Delivery delays – affecting project progress and production line stability Global layout, zero delivery delays

Global layout, zero delivery delays Deep customization capabilities to solve complex needs

Deep customization capabilities to solve complex needs Worry-free compliance, global access

Worry-free compliance, global access Cost optimization throughout the entire life cycle

Cost optimization throughout the entire life cycle