A cable gland is a mechanical device used to anchor and seal the end of a cable entering a housing or equipment. It provides:

-

Environmental protection (sealing against water, dust, and chemical exposure)

-

Mechanical anchoring (strain relief)

-

Electrical grounding or EMC contact, if needed

What Are the Main Cable Gland Types?

-

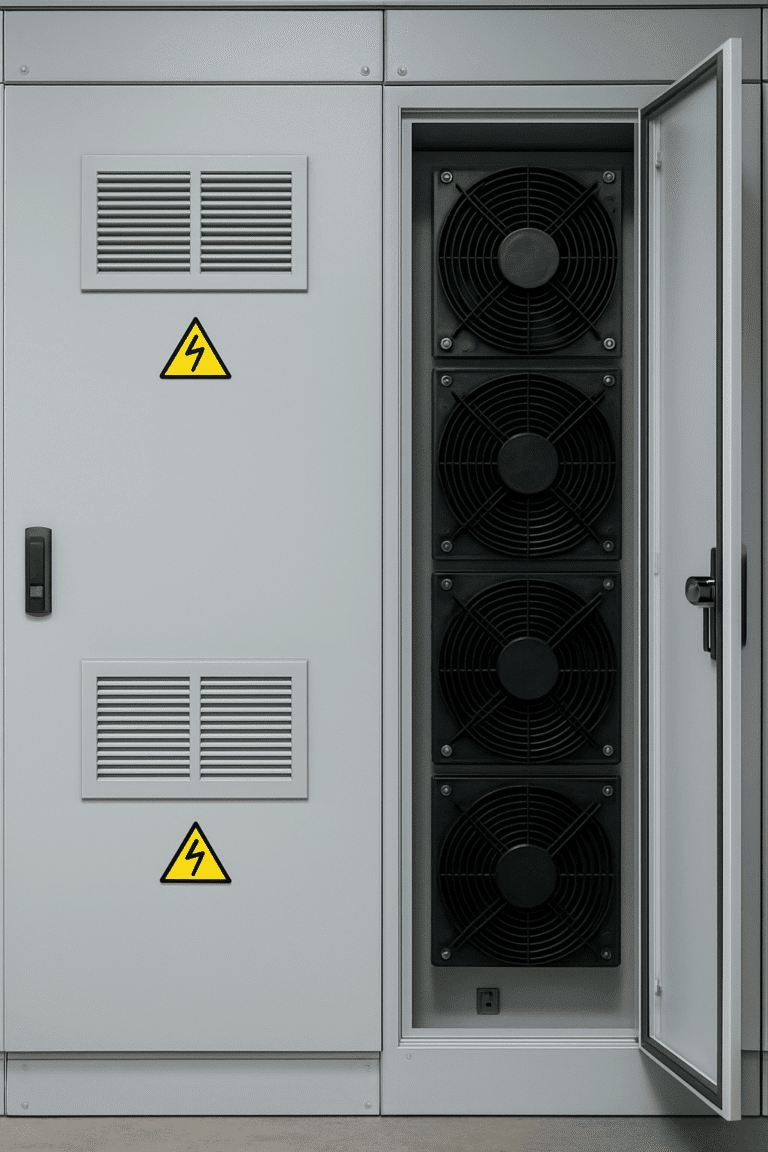

Nylon (Plastic) Cable Glands – Lightweight, cost-effective, IP66/68 rated

-

Brass Cable Glands – Rugged, EMI shielding, often used in control systems

-

Stainless Steel Glands – High corrosion resistance for food, marine, or chemical industries

Cable glands (also known as cable and gland systems) are essential for sealing, securing, and protecting cables as they pass into electrical enclosures. Choosing the right gland type ensures safety, waterproofing, EMC control, and long service life.

Key Facts Most People Don’t Know:

-

Material matters – PVC glands (white gland) are lightweight and corrosion‑resistant for indoor use; brass cable glands provide superior strength and grounding for industrial or hazardous areas.

-

Waterproofing is not just IP rating – True waterproof cable glands depend on correct cable fit, O‑ring quality, and proper tightening torque. Even IP68 cable glands can fail if installed incorrectly.

-

Thread type differences – M20 cable glands (metric) are not interchangeable with PG glands like PG 13.5; always confirm thread type before installation.

-

Cold & harsh environments – Use nylon or brass in low‑temperature or outdoor conditions where PVC can become brittle.

-

Multi‑cable efficiency – Cable gland plates and cable entry panels allow multiple cables to be sealed through one opening, reducing install time.

💡 Bottom line: Whether it’s m20 cable gland, m25 cable gland, or PG gland, correct selection and installation directly affect cable safety, enclosure protection, and long‑term reliability.

Delivery delays – affecting project progress and production line stability

Delivery delays – affecting project progress and production line stability