- FIND A DISTRIBUTOR

- APPLY FOR REGIONAL SALES

Innovative Technical Solutions

Enhancing Reliability & Efficiency with Advanced Thermal Management and Electrical Solutions

Download Brochure

Product Overview

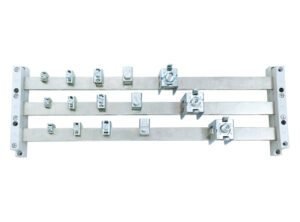

Busbar Terminals are key components in power distribution systems,

which realize centralized transmission and distribution of large currents through highly conductive busbars. They are designed for industrial control cabinets, data centers, large electrical equipment and new energy systems to ensure efficient, safe and reliable power supply.

Key Advantages

Made of high-quality copper or aluminum alloy materials to ensure low-resistance and low-loss power transmission.

Supports currents from tens of amperes to thousands of amperes to meet power distribution needs of various sizes.

Modular design saves space and is easy to install and maintain.

With short-circuit protection, overload protection and grounding functions to ensure stable operation of the system.

The number of busbar terminals can be easily increased or decreased according to actual needs to adapt to future expansion needs.

Product Catagories

Busbar Terminal

| wdt_ID | wdt_created_by | wdt_created_at | wdt_last_edited_by | wdt_last_edited_at | Model | Thickness | Wiring Dimension | Stack Space | Torque | Packing |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | SU 201 | 4-5mm | 1-4mm² | — | 2Nm | 50pcs | ||||

| 2 | SU 202 | 4-5mm | 2.5-16mm² | 8×8mm | 3Nm | 50pcs | ||||

| 3 | SU 203 | 4-5mm | 16-50mm² | 10.5×11mm | 6-8Nm | 50pcs | ||||

| 4 | SU 204 | 4-5mm | 35-70mm² | 16.5×15mm | 10-12Nm | 50pcs | ||||

| 5 | SU 205 | 4-5mm | 70-185mm² | 22.5×20mm | 12-15Nm | 50pcs | ||||

| 6 | SU 206 | 9-10mm | 1-4mm² | — | 2Nm | 50pcs | ||||

| 7 | SU 207 | 9-10mm | 2.5-16mm² | 8×8mm | 3Nm | 50pcs | ||||

| 8 | SU 208 | 9-10mm | 16-50mm² | 10.5×11mm | 6-8Nm | 50pcs | ||||

| 9 | SU 209 | 9-10mm | 35-70mm² | 16.5×15mm | 10-12Nm | 50pcs | ||||

| 10 | su 300 | 9-10mm | 70-185mm² | 22.5×20mm | 12-15Nm | 50pcs |

Busbar Terminal

| wdt_ID | wdt_created_at | wdt_last_edited_by | wdt_last_edited_at | Busbar terminal | Connection | Terminal Space WxH | Max Current | Packing | Model | Order Code |

|---|---|---|---|---|---|---|---|---|---|---|

| 9 | Universal conductor terminal | 1.5~16mm² | 7.5x7.5 | 180A | 100 | LP180A1605 | 5010.073 | |||

| 10 | 5mm flat busbars | 4~35mm² | 10.5x11 | 270A | 50 | LP270A3505 | 5010.074 | |||

| 11 | 5mm flat busbars | 16~70mm² | 14x14 | 400A | 25 | LP400A7005 | 5010.075 | |||

| 12 | 5mm flat busbars | 16~120mm² | 17x15 | 440A | 25 | LP440A12005 | 5010.076 | |||

| 13 | 10mm flat busbars | 1.5~16mm² | 7.5x7.5 | 180A | 100 | LP180A1610 | 5010.077 | |||

| 14 | 10mm flat busbars | 4~35mm² | 10.5x11 | 270A | 50 | LP270A3510 | 5010.078 | |||

| 15 | 10mm, double-T and triple-T section | 16~70mm² | 14x14 | 400A | 25 | LP400A7010 | 5010.079 | |||

| 16 | 10mm, double-T and triple-T section | 16~120mm² | 17x15 | 440A | 25 | LP440A12010 | 5010.080 |

Busbar terminal block

| wdt_ID | wdt_created_by | wdt_created_at | wdt_last_edited_by | wdt_last_edited_at | Model | Order Code | Wire Diameter (mm²) | Thickness (mm) |

|---|---|---|---|---|---|---|---|---|

| 1 | LP32A0405 | 5010.15 | 0.5-4 | 5 | ||||

| 2 | LP32A0410 | 5010.151 | 0.5-4 | 10 | ||||

| 3 | LP80A1605 | 5010.152 | 1.5-16 | 5 | ||||

| 4 | LP80A1610 | 5010.153 | 1.5-16 | 10 |

Applications

As the connection point of the main power supply line and branch circuit, it realizes efficient power distribution.

Provides stable and reliable power supply for server cabinets to ensure the continuity of data processing.

Such as solar power stations and wind farms, used for connecting battery energy storage systems and inverters to the power grid.

Such as motor control centers and switchboards, to achieve the integration of power transmission and control.

Basic Knowledge

Why Choose Leipole?

Leipole provides one-stop solutions:

💎 Global layout, zero delivery delays

🔧 Deep customization capabilities to solve complex needs

🌍 Worry-free compliance, global access

🚀 Cost optimization throughout the entire life cycle

Customization Process

Professional engineers deeply understand your equipment parameters, application environment, and special requirements.

R&D teams develop optimal heat dissipation solutions based on your needs, including airflow calculations and installation planning.

Provide samples for real-environment testing, collect data feedback, and ensure solution effectiveness.

After confirming the solution, production follows strict ISO9001 quality management systems to ensure batch stability.

FAQ

Inquiry

Related Products

Related Articles

Efficient airflow management in data centers is critical to maintaining stable IT equipment performance and reducing energy waste. Modern cooling...

In the actual operation of railway and urban rail transit system equipment, cabinet microenvironments such as heat dissipation, dust, and...

The temperature rise in medium-voltage switchgear has always been a key concern for customers. Due to design, manufacturing, and installation...

Why Is Proper Airflow Evaluation So Critical? In industrial fan environments—think electrical cabinets, energy storage systems, and EV charging stations—your...

Industrial leader in enclosure thermal management

Copyright © 2025. All rights reserved.