The temperature rise in medium-voltage switchgear has always been a key concern for customers. Due to design, manufacturing, and installation issues, the temperature often exceeds standard limits. Currently, a common practice is to operate at only 70% of the product’s rated current; even then, excessive temperature can still affect safe operation.

For high-current switchgear, forced air cooling using axial fans is an economical and effective solution. Fan placement and airflow are critical design factors, but fan quality and other issues may prevent continuous full-capacity operation. By conducting DOE tests on a 4000A switchgear—switching off the four busbar and trolley compartment fans on top of the cabinet separately and reducing current to measure maximum temperature rise—the resulting regression equations allow calculation of temperature rise. Proper derating ensures safe operation, and increasing fan airflow can further guarantee the switchgear operates safely under overcurrent conditions.

Causes of High Temperature Rise in Switchgear

The main reasons for excessive temperature rise in electrical cabinets and switchgear include:

a. High primary current;

b. Switchgear with relatively small current but requiring a high protection level (Enclosure with IP rating);

c. Operation in high ambient temperature environments;

d. Low conductivity of conductor materials, often due to insufficient purity of raw materials;

e. Improper installation and maintenance, such as poor surface treatment during busbar processing, connection, and assembly—uneven or rough surfaces, failure to apply conductive grease—which reduces the effective contact area, increases resistance, and causes overheating;

f. Surface oxide film resistance, loose busbar bolts, and similar issues.

Using a cooling fan or axial fan for forced air cooling not only effectively reduces the temperature rise in switchgear but also compensates for overheating caused by the above factors.

Design Solutions for Air Cooling in Switchgear

Heat dissipation relies on radiation, convection, and conduction. Among these, convection is the key factor in complete equipment cooling. Natural ventilation in standard enclosures (with IP4X or lower) can dissipate about 1000W of heat. Increasing the size of copper busbars can also reduce temperature rise.

However, for switchgear rated above 3150A, radiation, conduction, and natural convection are not sufficient to balance the internal heat and maintain temperature rise within standards. Installing axial fans for forced air cooling is the most economical and effective solution. Table 2 shows the main ohmic loss power parts of a 4000A switchgear.

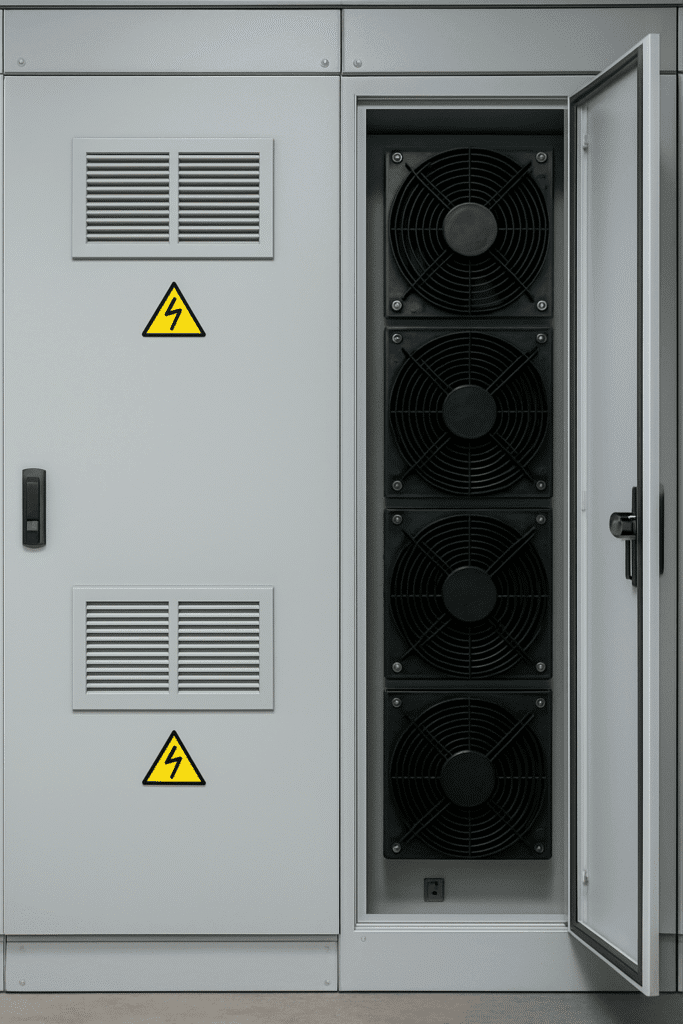

By setting industrial axial fans inside the cabinet and large axial fans at the top, hot air inside the cabinet is exchanged with external air, achieving an ideal convection process. This is essential for high-current switchgear.

2.1 Fan Position

The selection of an ac axial fan or other axial fans must consider power, airflow, and long-term service life. The design of ventilation holes and airflow paths in the enclosure should ensure efficient circulation: external air → axial fan → conductors inside the cabinet → exhaust fans at the top. At the same time, protection level, internal arc fault resistance, and ease of maintenance must also be considered.

Typical fan placements include (see Figure 1):

-

Cable compartment bottom: cold air enters through rear ventilation holes, cooling internal components, and hot air is expelled from the top.

-

Circuit breaker compartment bottom: cold air enters from the front lower partition, cooling the breaker and exhausting hot air upward.

-

Circuit breaker compartment top: hot air is extracted from the top to reduce breaker temperature.

-

Busbar compartment top: hot air is extracted from the top to lower busbar heating.

When using only a breaker compartment axial fan, it should be positioned at the air inlet, using the sealed space beneath the base plate as a static pressure box to convert dynamic pressure into static pressure, ensuring even airflow distribution. In this case, fan static pressure and outlet pressure have a linear relationship, and with the same flow and pressure, a higher static pressure results in less energy loss and longer airflow distance.

Thus, in many cases, a single cooling fan at the top or bottom can meet temperature rise requirements. If not sufficient, top and bottom fans must work together.

3.Choosing the Right Axial Fan for Switchgear

Fan efficiency is critical. With IP4X protective mesh, the pressure loss coefficient is 0.8. According to the thermal balance formula, radiation and natural convection in the breaker compartment account for about 250W, while the total heat generation is 1392W. This leaves 1142W of heat that requires forced cooling with axial fans.

Therefore, the position and airflow of fans in high-current air-cooled switchgear are extremely important. Through experiments with different fan airflow levels and various currents, temperature rise values can be determined. By applying DOE (Design of Experiments), transfer equations can be established to calculate possible temperature rises under specific conditions. With more experimental factors, regression analysis can provide more reliable equations to guide actual operation.

For end users and designers, working with experienced axial fan manufacturers ensures the best balance of airflow, durability, and efficiency.