Overheating kills equipment. Wrong enclosure size or cooling specs cause failures. Want reliable systems? Let’s nail the right choices. NEMA 4X

To size enclosures, calculate internal air volume, measure heat load with thermal imaging, and choose NEMA 4X for harsh environments. This ensures cooling efficiency and equipment reliability.

I’ve seen projects fail due to bad sizing or ignored heat loads. Stick with me to learn practical steps for perfect cooling.

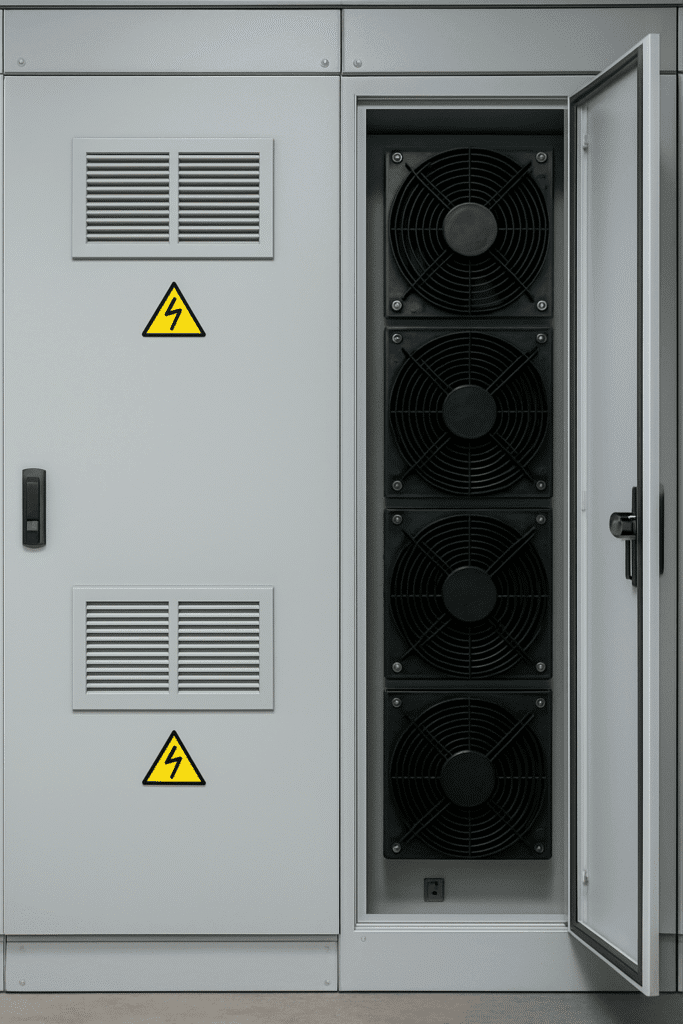

Enclosure Dimensions: More Than Just LxWxH

Enclosure size isn’t just length, width, and height. Internal air space matters more. Cable penetrations and components block airflow, reducing effective volume. I always add a 20% safety margin for dynamic systems like EV chargers.

Key Considerations

| Factor | Impact |

| Internal Air Space | Obstructions cut usable volume by 10-20%. |

| Cable Penetrations | Reduce airflow, needing larger fans. |

| Safety Margin | 20% extra volume prevents overheating. |

In a wind turbine project, I found tall enclosures used natural airflow better with top exhausts. Wide cabinets needed dual side fans to avoid dead zones. Shallow enclosures forced low-profile fans, so I added fan tray extensions to boost airflow. These tweaks kept systems cool and reliable.

Heat Load Math That Matters (Not Textbook Formulas)

Heat load calculations miss hidden sources. VFD harmonics and solar gain on outdoor units add heat. Nameplate watts lie—PLCs and transformers produce more heat than specs show.

Hidden Heat Sources

| Source | Real Heat Output |

| VFDs | 35% waste heat at 50% load. |

| PLCs | 85% heat from power supplies. |

| Solar Gain | Adds 20% heat in outdoor setups. |

In a 5kW panel project, thermal imaging showed 7.5kW heat due to harmonics. I used a Fluke analyzer to measure real heat during peak cycles. My checklist includes 14 factors like inrush heat and shutdown inertia to avoid surprises in industrial setups.

NEMA 4X Decoded – When Corrosion Becomes the Real Enemy

NEMA 4X protects against corrosion. Salt spray near coasts or chemical washdowns in pharma plants demand 316 stainless steel. Standard coatings fail fast in harsh environments.

NEMA Ratings Comparison

| Environment | Minimum Rating | When 4X Is Needed |

| Salt Spray | NEMA 3R | Coastal sites (<5 miles). |

| Chemicals | NEMA 4 | Food/pharma washdowns. |

| H2S Gas | NEMA 4X | Oil/gas plants. |

In a coastal EV charger project, powder-coated enclosures corroded in months. Switching to NEMA 4X with zinc-nickel plating saved downtime. My decision flowchart helps pick NEMA 12, 4, or 4X based on site conditions, ensuring long-term protection.

The Triangulation Method for Perfect Cooling Matches

I combine enclosure size, heat load, and thermal imaging for accurate cooling. Temporary cooling units test assumptions. This method catches errors before they cause failures.

Triangulation Steps

| Step | Tool/Method |

| Size Check | Measure internal air volume. |

| Heat Load | Use thermal imaging for real data. |

| Test Cooling | Deploy temporary units to validate. |

In a pharma plant, condensation wrecked cabinets. I used thermal imaging and temporary coolers to find the right NEMA 4X fans. This approach cut humidity issues and kept production running smoothly.

Your Next-Step Protocol

Start with accurate sizing. Measure heat with tools like Fluke analyzers. Choose NEMA 4X for harsh environments. Test cooling setups before final installation.

Action Checklist

| Task | Why It Matters |

| Measure Volume | Ensures enough air for cooling. |

| Check Heat | Catches hidden sources like VFDs. |

| Pick NEMA 4X | Protects against corrosion. |

I once saved a petrochemical plant $23k by switching to NEMA 4X fans with PTFE bearings. Follow these steps to avoid downtime and boost equipment life in your projects.

Conclusion

Size enclosures right, measure real heat, and use NEMA 4X for tough conditions. These steps ensure cooling success and long-lasting equipment.