Your critical electrical components face constant threats. Harsh conditions can cause unexpected failures, leading to costly downtime. It’s a battle you need to win. Electrical Enclosure

Superior electrical enclosure performance is vital in harsh environments because it directly protects sensitive internal components from damaging external factors, ensuring operational reliability, extending equipment lifespan, and maintaining safety.

Understanding these threats is the first step. If you’ve ever seen a system fail due to environmental factors, you know the frustration. But how do we define these “harsh environments,” and what makes a high-performance enclosure the right defense? Let’s explore why robust protection isn’t just a feature—it’s a necessity for anyone relying on sensitive electronics in tough places.

What Truly Constitutes “Harsh Environments” That Threaten Internal Enclosure Components?

When I talk about “harsh environments,” I’m not just referring to dramatic weather. From my experience, these are any conditions that can degrade, damage, or destroy the delicate electronics housed within your electrical enclosures. It’s a broad spectrum, and the specific threats can vary wildly depending on the industry and location. For instance, in manufacturing plants, you might deal with fine metallic dust that can cause short circuits. In coastal regions, the salty air is incredibly corrosive. Agricultural settings often have high levels of particulate matter and sometimes chemicals. Even a seemingly clean data center can become harsh if the cooling fails, leading to overheating. The key is that these environments present persistent challenges that standard, unprotected components simply cannot withstand. Recognizing these varied threats is crucial for selecting the right protective measures.Electrical Enclosure

Common Environmental Threats

| Threat Type | Description | Impact on Components |

| Moisture/Water | Rain, snow, high humidity, washdowns, submersion | Corrosion, short circuits, insulation breakdown |

| Dust/Particulates | Industrial dust, dirt, sand, agricultural debris | Overheating (insulation), abrasion, conductive paths |

| Corrosive Agents | Chemicals, salt spray, acidic gases | Material degradation, connection failure, rust |

| Temperature | Extreme heat (direct sun, industrial processes) or cold (outdoor, refrigerated) | Component failure, reduced lifespan, erratic behavior |

Understanding these specific elements allows us to appreciate why a generic box just won’t cut it. The enclosure needs to be a fortress, tailored to the specific enemies it will face.

How Can Extreme High or Low Temperatures Silently “Kill” Sensitive Electronics Inside Your Enclosure?

Temperature is a silent killer. I’ve seen perfectly good systems fail because nobody accounted for the ambient temperature swings or the heat generated by the components themselves. Extreme heat, whether from direct sun exposure in a desert installation or a nearby furnace in a foundry, can cause components to operate outside their specified temperature range. This leads to premature aging, intermittent faults, and eventual breakdown. Resistors can drift, capacitors can dry out, and processors can become unstable. On the other side, extreme cold, like in outdoor installations in northern climates or inside refrigerated facilities, brings its own set of problems. Materials can become brittle, LCD screens can freeze, and some components simply won’t start in sub-zero conditions. Condensation can also form when cold components are exposed to warmer, moist air, leading to short circuits. This is why thermal management, including appropriately sized enclosure heaters like those offered by LEIPOLE to maintain stable internal temperatures, is not a luxury but a core part of a reliable enclosure system.

Temperature’s Impact on Electronics

| Temperature Condition | Potential Effect on Electronics | Consequence |

| Excessive Heat | Components exceed operational limits, accelerated aging | Reduced lifespan, instability, sudden failure |

| Extreme Cold | Material brittleness, slower component response, startup issues | Mechanical failure, operational delays |

| Temperature Cycling | Expansion/contraction stress on solder joints, connections | Intermittent faults, connection breaks |

| Internal Heat Buildup | No escape for heat generated by components | Overheating, similar to external high temps |

It’s a delicate balance, and maintaining the internal temperature within the components’ operational limits is paramount for long-term reliability.

How Can Extreme High or Low Temperatures Silently “Kill” Sensitive Electronics Inside Your Enclosure?

Temperature is a silent killer. I’ve seen perfectly good systems fail because nobody accounted for the ambient temperature swings or the heat generated by the components themselves. Extreme heat, whether from direct sun exposure in a desert installation or a nearby furnace in a foundry, can cause components to operate outside their specified temperature range. This leads to premature aging, intermittent faults, and eventual breakdown. Resistors can drift, capacitors can dry out, and processors can become unstable. On the other side, extreme cold, like in outdoor installations in northern climates or inside refrigerated facilities, brings its own set of problems. Materials can become brittle, LCD screens can freeze, and some components simply won’t start in sub-zero conditions. Condensation can also form when cold components are exposed to warmer, moist air, leading to short circuits. This is why thermal management, including appropriately sized enclosure heaters like those offered by LEIPOLE to maintain stable internal temperatures, is not a luxury but a core part of a reliable enclosure system.

Temperature’s Impact on Electronics

| Temperature Condition | Potential Effect on Electronics | Consequence |

| Excessive Heat | Components exceed operational limits, accelerated aging | Reduced lifespan, instability, sudden failure |

| Extreme Cold | Material brittleness, slower component response, startup issues | Mechanical failure, operational delays |

| Temperature Cycling | Expansion/contraction stress on solder joints, connections | Intermittent faults, connection breaks |

| Internal Heat Buildup | No escape for heat generated by components | Overheating, similar to external high temps |

It’s a delicate balance, and maintaining the internal temperature within the components’ operational limits is paramount for long-term reliability.

Why are Humidity and Condensation the Number One Culprits for Short Circuits and Corrosion Inside Electrical Enclosures?

In my years in the field, if I had to pick the most insidious threat to electrical components, it would be moisture in its various forms – especially humidity and condensation. It’s not always a dramatic flood; often, it’s the slow, creeping attack of water vapor. High ambient humidity means there’s a lot of moisture in the air. When the temperature inside an enclosure drops below the dew point, or when warm, moist air comes into contact with cooler surfaces inside the enclosure, that vapor condenses into liquid water. This water can then pool on circuit boards, seep into connectors, and coat sensitive parts. The results? Corrosion is a big one, eating away at metal contacts and traces, leading to high-resistance connections or outright breaks. Short circuits are another major risk, as water can create unintended pathways for electricity. This can cause immediate component failure or, worse, intermittent faults that are a nightmare to diagnose. Even if an enclosure has a good seal, managing internal condensation with solutions like enclosure heaters and hygrostats, such as those provided by LEIPOLE, is critical to combat this pervasive enemy.Electrical Enclosure

Moisture’s Destructive Path

| Moisture Manifestation | Mechanism of Damage | Typical Outcome |

| High Ambient Humidity | Increased moisture content in the air surrounding components | Higher risk of condensation, supports corrosion |

| Condensation | Water vapor turns to liquid on cooler surfaces | Short circuits, corrosion, insulation breakdown |

| Direct Water Ingress | Rain, splashes, washdowns bypassing seals | Immediate short circuits, widespread corrosion |

| Corrosive Vapors | Moisture combining with airborne chemical agents | Accelerated and aggressive corrosion of metals/plastics |

That’s why preventing moisture ingress and managing internal humidity are top priorities in enclosure design.

How Can a High-Performance Electrical Enclosure System Effectively Address These Environmental Challenges and Protect Internal Equipment?

A high-performance electrical enclosure system isn’t just a box; it’s an engineered solution designed to create a stable micro-environment for the sensitive equipment inside. My experience has shown that the first line of defense is always the physical barrier. This means selecting an enclosure with the correct IP (Ingress Protection) or NEMA rating for the specific environmental challenges. For example, an IP55 rating ensures protection against powerful jets of water and is dust-tight. Beyond the rating, the material of the enclosure is critical. For corrosive environments like chemical plants or coastal areas with salt spray, specific grades of stainless steel (like 316L) or robust non-metallic materials are essential to prevent the enclosure itself from degrading. The design of the seals, the type of gasket material used, and the construction of doors and cable entry points all contribute to preventing the ingress of moisture, dust, and corrosive agents. This robust shell is the foundation upon which other protective measures, like thermal management, build to ensure comprehensive protection.Electrical Enclosure

Key Enclosure Defense Mechanisms

| Feature/System | How It Protects | Environmental Challenge Addressed |

| High IP/NEMA Rating | Provides a certified level of sealing against solids and liquids | Dust, dirt, water (rain, spray, submersion) |

| Material Selection | Resists chemical attack, UV radiation, and physical impact | Corrosive agents, outdoor exposure, impacts |

| Robust Sealing | Gaskets, door design, cable glands prevent contaminants from entering | Moisture, dust, particulates, gases |

| Structural Integrity | Withstands physical stresses, vibrations, and potential impacts in the environment | Mechanical shocks, industrial vibrations |

By focusing on these aspects, a high-performance enclosure acts as a primary shield, safeguarding the valuable assets within.

Besides IP Rating, What Other Key Performance Indicators Determine an Enclosure’s Performance in Harsh Environments?

While the IP or NEMA rating is a fundamental starting point, I’ve learned that relying solely on it can be a mistake in truly harsh environments. Several other key performance indicators (KPIs) are crucial. Material resistance is high on my list. This isn’t just about corrosion; it includes UV resistance for outdoor applications, resistance to specific chemicals if present, and even impact resistance. The structural integrity of the enclosure—how well it holds its shape and protects against physical blows or vibrations—is also vital, especially in industrial or mobile applications. Then there’s the integration capability for thermal management solutions. An enclosure might have a great IP rating, but if it can’t effectively accommodate heaters, air conditioners, or fans without compromising its seal, its overall performance is diminished. Compliance with industry-specific standards (like ATEX for explosive atmospheres) is another non-negotiable KPI in certain applications. Finally, ease of maintenance and accessibility, while not directly a “performance” metric against the environment, impacts long-term reliability because a difficult-to-maintain enclosure might lead to compromised seals or neglected components over time.

Critical Performance Indicators Beyond IP Rating

| Performance Indicator | Significance in Harsh Environments | Why It Matters |

| Material Durability | Resistance to corrosion, UV, chemicals, temperature extremes | Ensures long-term structural integrity and protection |

| Mechanical Strength | Ability to withstand impacts, vibrations, and operational stresses | Prevents physical damage to enclosure and internal components |

| Thermal Management Integration | Compatibility with heating, cooling, and ventilation systems | Allows for stable internal climate control without leaks |

| Seal Longevity & Quality | Durability of gaskets under compression and environmental exposure | Maintains ingress protection over the enclosure’s lifespan |

| Certifications/Compliance | Meeting specific industry or safety standards (e.g., UL, ATEX) | Ensures suitability for application and regulatory adherence |

Considering these additional KPIs provides a more holistic view of an enclosure’s true ability to protect.

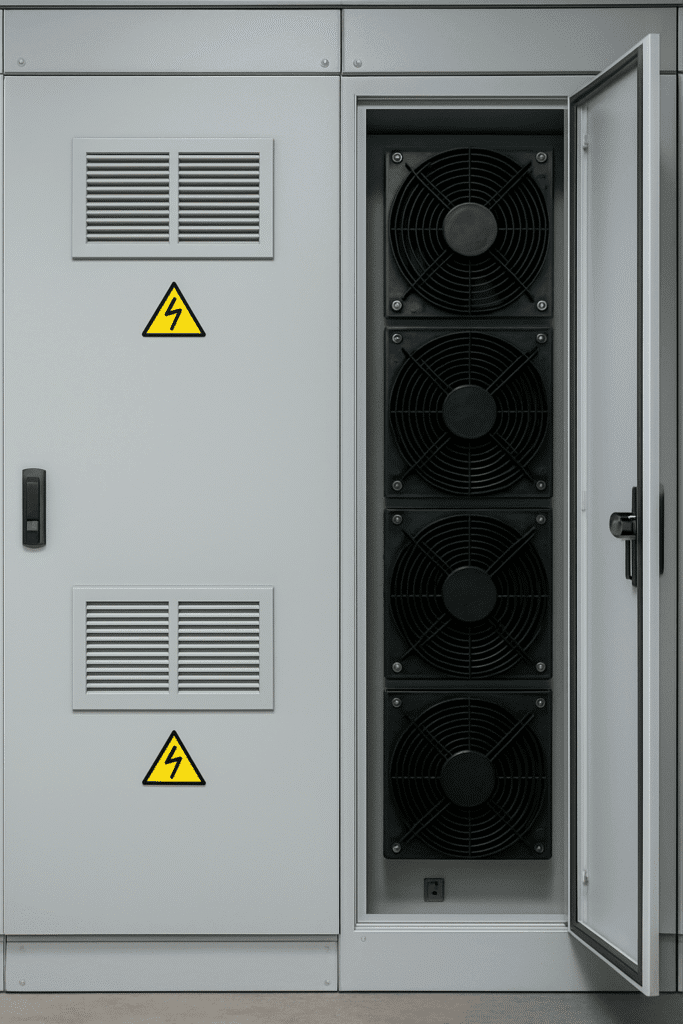

How to Ensure a Stable Internal Enclosure Environment Through Active Thermal Management (Heating/Cooling/Ventilation)?

Simply sealing an enclosure isn’t always enough, especially when the external environment is extreme or the internal components generate significant heat. This is where active thermal management becomes essential. I’ve seen many projects succeed because of a well-thought-out thermal strategy. For cold environments or to combat condensation, enclosure heaters, like the PTC heaters LEIPOLE designs, are crucial. They gently warm the air inside, keeping components above their minimum operating temperature and preventing moisture from condensing on surfaces. In hot environments, or where internal components like VFDs and power supplies generate a lot of heat, cooling solutions are necessary. These can range from simple filter fans, like LEIPOLE’s FKL99 series with high airflow options , for moderate heat loads, to enclosure air conditioners for more demanding cooling requirements, or even vortex coolers for spot cooling. Ventilation, managed by thermostats and hygrostats , helps to exchange air and manage humidity. The goal is to create a stable internal climate, keeping the temperature and humidity within the optimal operating range of the enclosed electronics. This active approach is key to preventing thermal stress and ensuring long-term reliability.Electrical Enclosure

Active Thermal Management Solutions

| Thermal Solution | Primary Function | Best Suited For |

| Enclosure Heaters | Prevent low temperatures, control condensation | Cold environments, fluctuating temperatures |

| Filter Fans | Expel hot air, introduce cooler ambient air | Moderate heat loads, relatively clean environments |

| Air Conditioners | Actively cool internal air, closed-loop system | High heat loads, dirty/corrosive environments |

| Heat Exchangers | Transfer internal heat to the outside via a sealed interface | Moderate heat loads, maintains enclosure seal |

| Thermostats/Hygrostats | Control heating, cooling, and ventilation devices | Precise environmental control, energy efficiency |

Implementing the right combination of these active solutions is critical for achieving that stable internal environment necessary for equipment longevity.