- FIND A DISTRIBUTOR

- APPLY FOR REGIONAL SALES

Innovative Technical Solutions

Enhancing Reliability & Efficiency with Advanced Thermal Management and Electrical Solutions

Download Brochure

Product Overview

Key Advantages

Product Catagories

| wdt_ID | wdt_created_by | wdt_created_at | wdt_last_edited_by | wdt_last_edited_at | Model | Order number | Cable diameter Φ (mm) | B mm | H mm |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB6-12 | 5011.001 | 6–12 | 21 | 23 |

| 2 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB12-18 | 5011.002 | 12–18 | 24 | 75 |

| 3 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB18-22 | 5011.003 | 18–22 | 27 | 70 |

| 4 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB22-30 | 5011.004 | 22–30 | 39 | 85 |

| 5 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB30-38 | 5011.005 | 30–38 | 45 | 90 |

| 6 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB38-42 | 5011.006 | 38–42 | 47 | 95 |

| 7 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB42-50 | 5011.007 | 42–50 | 57 | 120 |

| 8 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB50-64 | 5011.008 | 50–64 | 70 | 130 |

| 9 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB12.2 | 5011.009 | 6–12 | 16 | 75 |

| 10 | Kiva | 08/07/2025 07:29 AM | Kiva | 08/07/2025 07:29 AM | UB14.2 | 5011.01 | 12–14 | 18 | 77 |

| Model | Order number | Cable diameter Φ (mm) | B mm | H mm |

Applications

Basic Knowledge

● Design: Built for security and optimal conductivity

● Standards: CE and RoHS compliant

1. Beyond Basic Securing: Strain Relief & Bend-Radius Control

Strain relief: A properly chosen clamp doesn’t just hold a cable; it prevents conductors from pulling on terminations under tension. In high-vibration environments (e.g., machine tools), a misplaced clamp can lead to intermittent faults far from the panel.

Bend-radius maintenance: Multi-cable clamps with built-in radius control keep each cable bend above its minimum spec, reducing conductor fatigue and insulation cracking over time.

2. Material & Environmental Secrets

Nylon vs. Stainless Steel: Nylon clamps (UL94 V0 rated) are lightweight and resist many chemicals, but become brittle below –10 °C. Stainless-steel clamps, often overlooked, excel in sub-zero or corrosive (marine, chemical) atmospheres—no UV or solvent-breakdown.

Elastomer inserts: Rubber-lined or cushioned clamps dampen vibration and protect insulation. In precision instrumentation panels, this can reduce microphonic noise on sensitive signal lines by up to 80%.

3. Installation & Layout Best Practices

Clamping pitch: Industry rule of thumb is one clamp every 30 cm for static runs, but every 10–15 cm for mobile or vibrating assemblies. Too few, and cables sag; too many, and cable harnesses become rigid, transferring vibration to terminations.

Torque & compression: Over-tightening metal clamps can deform cable jackets. Use a torque-limited screwdriver or hand-feel gauge. Aim for firm grip without crushing—the sweet spot extends clamp life by 3×.

4. Thermal Cycling & Expansion Management

In environments cycling from –40 °C to +85 °C, clamps must accommodate cable expansion. Rigid clamp spacing without expansion gaps causes insulation stress cracks. Plan “expansion joints” every 1 m of harness.

5. EMI Control & Grounding Integration

Shielded-cable clamps with integrated grounding tabs can bond cable shields directly to chassis ground, eliminating separate grounding straps. This is a game-changer in telecom racks where EMI regs are strict.

Avoid plastic clamps on screened power cables—use metal-backed clamps bonded with star washers for low-impedance earthing.

6. Fire-Safety & Outgassing Considerations

In critical infrastructure (data centers, hospitals), halogen-free, low-smoke-zero-halogen (LSZH) clamps prevent toxic fume release during fires. Many generic clamps off-gas corrosive acids, damaging sensitive electronics.

7. Modular & Retrofit Solutions

DIN-rail cable clamp modules let you preassemble harnesses on small TS 35 rails, then snap the entire block into new panels for rapid rebuilds. This cuts wiring time by 50% in repeat-build scenarios.

Stackable multi-tier clamps maximize vertical space in shallow enclosures, keeping power, signal, and data lines separated but bundled.

Why Choose Leipole?

💎 Certified quality & reliability – UL, CE, and RoHS certified for global standards

🚀 International Supply & Super Fast Shipping – Singapore & worldwide warehouses

🔬 Research & Testing – Our lab runs tests to ensure performance & endurance

🌱 Energy Saving & Eco Friendly – Low Power Consumption with super high airflow

Customization Process

Professional engineers deeply understand your equipment parameters, application environment, and special requirements.

R&D teams develop optimal heat dissipation solutions based on your needs, including airflow calculations and installation planning.

Provide samples for real-environment testing, collect data feedback, and ensure solution effectiveness.

After confirming the solution, production follows strict ISO9001 quality management systems to ensure batch stability.

FAQ

🔹 Q1: What is the maximum current rating of your Busbar Clamps?

💡 A: Our clamps are available in various models designed to handle different high-load requirements. Please contact our technical team for specific ratings.

🔹 Q2: Are these clamps compatible with both copper and aluminum busbars?

💡 A: Yes, our clamps are designed for excellent compatibility with both copper and aluminum busbars.

🔹 Q3: Do you offer custom sizes and configurations?

💡 A: Absolutely. We provide OEM/ODM services to customize clamps according to your project specifications.

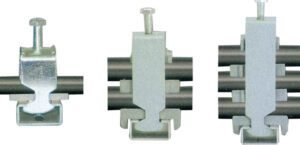

💡Heavy‑duty cable clamps secure and route large‑diameter cables in control panels, machinery, and outdoor installations, preventing cable movement and strain damage under vibration or load.

💡Stainless steel cable clamps provide exceptional corrosion resistance, making them ideal for marine, offshore, chemical, and outdoor applications exposed to salt, moisture, or industrial contaminants.

💡Adjustable cable clamps allow flexible positioning and re‑tightening of cables without full removal, enabling quick maintenance and cable re‑routing in modular panel layouts.

💡Cushioned cable clamps feature rubber or elastomer inserts that absorb vibration and protect cable insulation, especially for instrumentation, fiber optic, or high‑flex cables.

💡Yes. DIN rail‑mounted cable clamps snap directly onto TS 35 or TS 32 rails, allowing tool‑free installation and easy relocation during panel modifications.

Inquiry

Related Products

Related Articles

Efficient airflow management in data centers is critical to maintaining stable IT equipment performance and reducing energy waste. Modern cooling...

In the actual operation of railway and urban rail transit system equipment, cabinet microenvironments such as heat dissipation, dust, and...

The temperature rise in medium-voltage switchgear has always been a key concern for customers. Due to design, manufacturing, and installation...

Why Is Proper Airflow Evaluation So Critical? In industrial fan environments—think electrical cabinets, energy storage systems, and EV charging stations—your...

Industrial leader in enclosure thermal management

Copyright © 2025. All rights reserved.