In the actual operation of railway and urban rail transit system equipment, cabinet microenvironments such as heat dissipation, dust, and condensation increasingly affect the safe and stable operation of electrical and electronic equipment. Effective heat exchange and proper cabinet cooling are critical to maintain optimal enclosure cooling, preventing equipment failures and extending service life. Currently, the number of failures caused by inadequate cooling and environmental protection is increasing, drawing significant attention from technical personnel.

Fluctuating microenvironments are a cause of failure in mature and stable electrical and electronic products:

Electrical and electronic products rely on stable temperature, humidity, and dust conditions to maintain balanced heat dissipation, maintain dielectric strength, and prevent corrosion within their expected lifespan. However, the variable increase in dust caused by continuous heat dissipation disrupts this balanced heat dissipation. The ever-changing humidity and condensation, in turn, affect dielectric strength and corrosion progression in real time. These dynamic characteristics are the cause of failure in stable electrical and electronic products.

Cabinet Heat Dissipation and Dust Prevention

3.1 Are Dust Filters in IP55/54 Cabinets Dustproof?

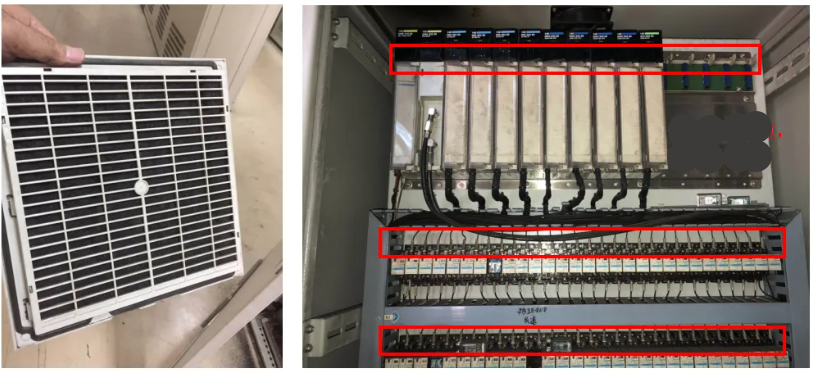

It is often believed that an IP5X cabinet equipped with an IP5X filter fan (also known as a fan and outlet filter or fan and filter) can prevent dust from entering the cabinet. What is the actual situation?

In reality, this does not effectively prevent dust from entering the cabinet. Dust will continue to enter the cabinet during operation, which can compromise cabinet cooling and reduce the efficiency of enclosure cooling. Figure 2 shows an IP5X air inlet filter installed in a cabinet. Dust has blackened the filter pads. Figure 3 shows dust accumulated on components inside a cabinet equipped with an IP5X filter fan and air window, which can further hinder heat exchange and impact the safe operation of electrical equipment.

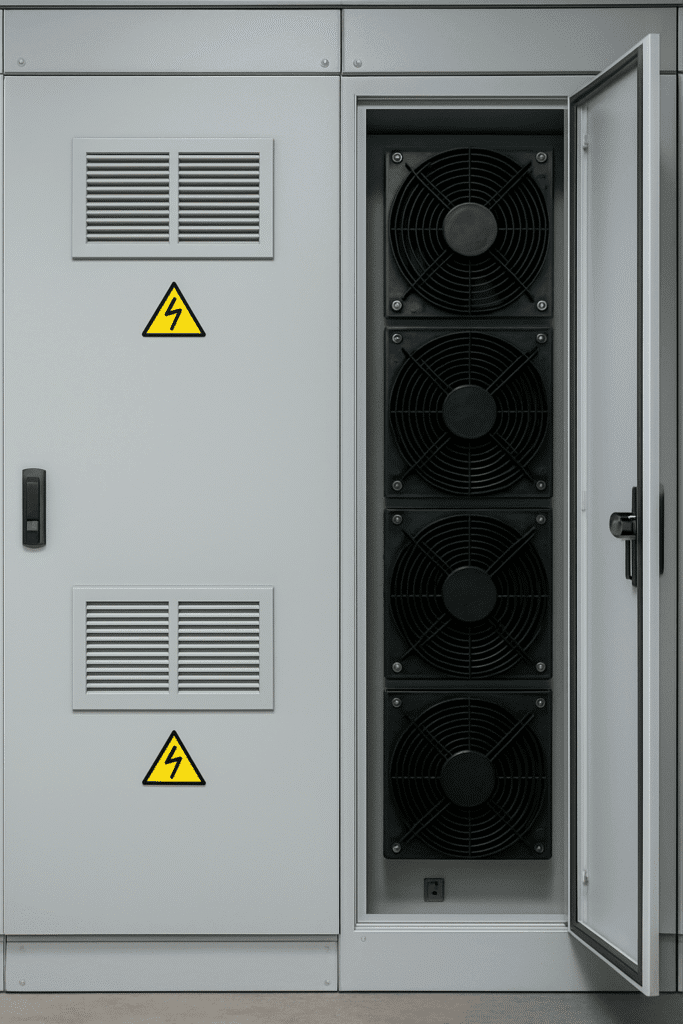

1) Type 1 Enclosure: When the pressure inside the enclosure is lower than the ambient atmospheric pressure during the operating cycle, for example due to thermal cycling (i.e., ventilation and cooling inside and outside the cabinet), the enclosure should be tested according to the Dust Protection Level 6 standard. This involves using a vacuum pump to simulate thermal cycling. A pressure differential of less than 2 kPa is required, requiring rapid pumping for 2 hours or slow pumping for 8 hours.

2) Type 2 Enclosure: When the pressure inside the enclosure is the same as the ambient atmospheric pressure, i.e., during static operation without ventilation and cooling inside and outside the cabinet, the enclosure should be tested according to the Dust Protection Level 5 standard. This test simulates no thermal cycling, without a vacuum pump, and lasts for 8 hours.

Summary:

According to the standard, IP5X enclosures with ventilation and cooling systems that require dust protection should utilize IP6X ventilation and dust protection devices.

Cabinet Heat Dissipation and Dust Control Solutions

Based on practical experience and standards for cabinet dust control, solutions for cabinets requiring heat dissipation and dust control are as follows:

1) Cabinet protection level ≥ IP5X

2) Cooling Device Options:

For the first enclosure type, which utilizes ventilation and cooling with a pressure differential between the inside and outside, an IP6X filter fan must be installed to provide both ventilation and dust protection.

For the second enclosure type, which utilizes cooling without a pressure differential between the inside and outside, a cabinet air conditioner must be installed.

3.4 Solution Comparison

| Solution Type | Cooling Method | Cooling Effect | Dustproof Effect | Power Consumption (for 2KW cooling) | Maintenance | Outdoor Application |

| Cabinet Air Conditioner | Refrigeration Cooling | Good | Good | ≥2.4KW (Cooling≈1.4KW + Condensate Removal≈1KW) | Refrigerant Replenishment ≈1~2 years | Possible |

| IP6X Filter Fan | Ventilation Cooling | Good | Good | ~0.13KW | Filter Replacement | Possible (IP65+ required) |

3.5 Differences between IP5X and IP6X Dustproof Designs

1) Difficulties with IP5X Filterfan Dust Prevention

Under wind pressure, the filter material deforms, increasing pores and gaps, making it less effective at preventing dust. This is the fundamental reason why many cabinets equipped with IP5X filterfans still experience significant dust ingress.

2) IP6X filter fan dustproofing requires superior structural design to ensure no deformation or gaps under 2kPa wind pressure, achieving both static and dynamic dustproofing.