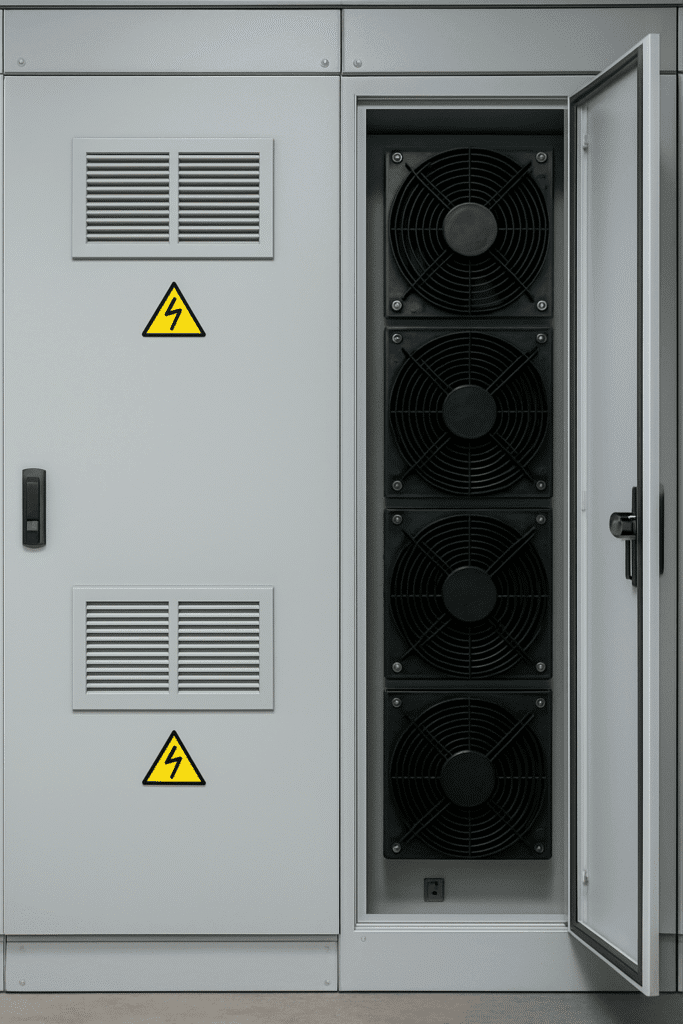

To select the right enclosure fan and avoid overheating, you must accurately calculate required airflow (CFM or m³/h), understand static pressure, choose the correct fan type (axial vs. centrifugal), and consider environmental conditions and component specifications.An overheating electrical cabinet is a ticking time bomb for your operations. Don’t let “heatstroke” cripple your valuable components and lead to costly downtime.

I’ve seen firsthand how the wrong fan, or no fan at all, can lead to disastrous consequences. It’s not just about randomly picking a fan; it’s a precise science. Feeling overwhelmed? Don’t be. Let’s break down the essential steps to ensure your electrical enclosure stays cool, and your equipment runs smoothly.

Step 1: How Much Airflow (CFM or m³/h) Does My Electrical Enclosure Actually Need for Effective Cooling?

This is the absolute starting point, and honestly, it’s where many people go wrong. You can’t just guess. Calculating the required airflow, usually measured in Cubic Feet per Minute (CFM) or cubic meters per hour (m³/h), involves understanding how much heat your internal components are generating and how much you need to cool them down.

The basic idea is to determine the heat load (Pin) inside your enclosure – that’s the sum of all the power dissipated by your devices in watts. Then, you need to decide on the maximum allowable internal temperature (Ti) – what’s the hottest your most sensitive component can safely operate at? Finally, you need to know the maximum ambient temperature (Ta) outside the enclosure. The difference between Ti and Ta (often called ΔT) is crucial.

A simplified formula often used is: Airflow (V) = Pin / (ρ * cp * ΔT), where ρ is air density and cp is the specific heat capacity of air. However, many manufacturers, including us at LEIPOLE, provide simplified calculators or charts to make this easier. For instance, our FKL99 series offers various airflow options to match specific needs. Remember, it’s not just about the fan’s maximum rated airflow; it’s about the airflow it can deliver against the resistance in your specific enclosure, which leads us to static pressure.

Axial Fans vs. Centrifugal Fans: Which One is Better Suited for My Enclosure Cooling Needs?

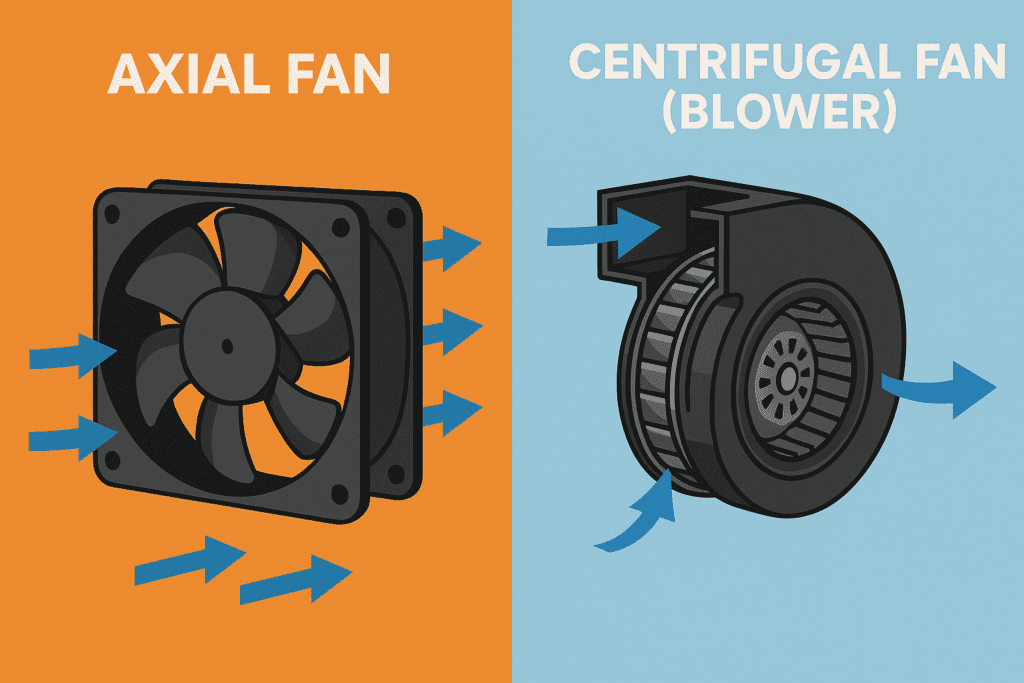

Once you know how much air you need to move, the next big question is what type of fan to use. The two main contenders for enclosure cooling are axial fans and centrifugal fans, and they behave quite differently.

Axial Fans: These are what most people picture when they think of a fan. The blades rotate around an axis and move air parallel to that axis, like a propeller. I’ve found axial fans are generally best for applications requiring high airflow rates where there’s low static pressure – meaning not a lot of resistance to airflow. Most filter fan units, like our FKL55 and FKL99 series, utilize axial fans because they are efficient at moving large volumes of air through relatively unobstructed paths. They are great for general enclosure ventilation. LEIPOLE offers a range of axial fans designed for powerful airflow solutions.

Centrifugal Fans (or Blowers): These fans draw air in axially (like an axial fan) but then discharge it radially, at a 90-degree angle, using the centrifugal force generated by a spinning impeller. I recommend centrifugal fans when you’re dealing with higher static pressure. Think of situations where the air has to be forced through dense filters, complex ductwork, or a tightly packed enclosure with many obstructions. They might not always move the same sheer volume of air as a similarly sized axial fan in free air, but they excel at maintaining airflow when faced with resistance. LEIPOLE also provides centrifugal fan designs for these more demanding scenarios.

Here’s a quick comparison:

| Feature | Axial Fan | Centrifugal Fan (Blower) |

| Airflow Path | Parallel to axis (straight through) | 90-degree turn (radial discharge) |

| Best For | High volume, low static pressure | Higher static pressure, more resistance |

| Pressure | Lower pressure capability | Higher pressure capability |

| Typical Use | General ventilation, filter fan units | Dense components, ductwork, high-resistance paths |

| LEIPOLE Lines | FKL55, FKL99 series | Specific centrifugal designs available |

Choosing the right type is crucial. Using an axial fan in a high-resistance application means it won’t move nearly as much air as you calculated, leading to overheating. Conversely, using a powerful centrifugal fan where it’s not needed might be overkill and potentially noisier or less energy-efficient.

How Important is Enclosure Static Pressure for Fan Selection? How Do I Assess It?

Static pressure is a term I find many people overlook, but it’s incredibly important. Think of it as the resistance or friction the air encounters as it tries to move through your enclosure. This resistance is created by everything inside: components, wiring, brackets, and especially air filters. The denser the internal layout or the finer the filter media, the higher the static pressure the fan will have to overcome.

Why does it matter? Every fan has a performance curve, which plots airflow (CFM or m³/h) against static pressure (often measured in inches of water or Pascals). A fan might be rated for, say, 100 CFM in “free air” (zero static pressure), but as soon as you put it in an enclosure with filters and components, the static pressure increases, and the actual airflow delivered by that fan will decrease. If you don’t account for this, you’ll end up with insufficient cooling.

Assessing it can be tricky without specialized equipment. However, you can make estimations:

- Filters: These are usually the biggest contributors. Filter manufacturers often provide static pressure drop data for their filters at different airflow rates. Pleated filter mats, like those used in Leipole’s FKL99 series, are designed to minimize airflow resistance compared to standard flat mats.

- Internal Obstructions: A densely packed enclosure will have higher static pressure than a sparsely populated one. Consider the path the air needs to take. Are there many sharp turns or blockages?

- Inlet/Outlet Grilles: Even the grilles themselves create some resistance.

When you select a fan, you must look at its performance curve and ensure it can deliver your calculated required airflow at the estimated static pressure of your specific enclosure setup. If the fan curve shows a steep drop in airflow as static pressure rises, it might not be suitable for a restrictive environment.

Besides Airflow, What Other Key Fan Parameters (e.g., Voltage, Power Consumption, Noise) Must I Pay Attention To?

Calculating airflow and understanding static pressure are foundational, but the job isn’t done yet. I always tell my clients to look at the complete picture. Several other fan parameters are critical for a successful and reliable installation.

First, Voltage and Frequency: This seems obvious, but it’s a common oversight. Ensure the fan’s rated voltage (e.g., 230V AC, 115V AC, 24V DC) and frequency (e.g., 50/60 Hz) perfectly match your available power supply. A mismatch can lead to fan failure or even damage to your power system.

Power Consumption (Watts): This is important for a couple of reasons. Firstly, it contributes to your overall energy bill. Choosing an energy-efficient fan can lead to cost savings over time. Secondly, the fan’s power consumption itself adds a small amount of heat to the enclosure. While usually minor, it’s good to be aware of, especially in very sensitive or tightly controlled thermal environments. LEIPOLE’s FKL55 series, for instance, is designed for superior cooling while minimizing energy consumption.

Noise Level (dB): This is a huge factor, especially if the enclosure is located in or near workspaces, or in environments where noise regulations are strict. Fan noise is typically measured in decibels (dB). A fan that provides excellent cooling but sounds like a jet engine might not be acceptable. Fan datasheets will specify the noise level, often at a certain distance.

Bearing Type: Fans typically use either sleeve bearings or ball bearings. Ball bearings generally offer a longer operational lifespan, can tolerate higher temperatures, and can be mounted in any orientation. Sleeve bearings are often more cost-effective but may have a shorter lifespan and might have restrictions on mounting orientation. This is a critical detail for long-term reliability.

Expected Lifespan (L10 or MTBF): Manufacturers often provide an expected operational lifespan, sometimes expressed as L10 (the time by which 10% of a sample of fans will have failed) at a specific operating temperature. Higher operating temperatures drastically reduce fan life.

Considering these parameters ensures the fan not only cools effectively but also integrates seamlessly and reliably into your system.

What Requirements Does My Application Environment (Temperature, Humidity, Dust) Impose on the IP Rating and Material of the Enclosure Fan?

The environment where your electrical enclosure operates plays a massive role in fan selection. You can’t just put any fan anywhere. I’ve seen systems fail quickly because an indoor-rated fan was used in a dusty factory or a humid outdoor setting.

Operating Temperature Range: Every fan has a specified operating temperature range (e.g., -10°C to +55°C for some Leipole models). [^1, 2] If your ambient temperature can exceed these limits, the fan may fail prematurely or not perform as expected. Consider both the lowest winter temperatures and the highest summer temperatures, plus any heat from nearby processes.

Humidity: High humidity can lead to condensation inside the fan motor or on its electronics, causing corrosion and failure. While the fan itself helps move air, its own construction needs to be suitable for the ambient humidity levels.

Dust and Water (IP Rating): This is where the Ingress Protection (IP) rating becomes critical for the fan unit (especially filter fans). An IP rating consists of two digits:

- The first digit indicates protection against solid objects (dust, dirt).

- The second digit indicates protection against water. For example, an IP54 rating means the fan unit is protected against dust ingress (limited ingress, no harmful deposits) and water splashing from any direction. Leipole’s FKL55 series, for example, can have an IP54 or even IP55 rating. If your environment is dusty or subject to washdowns, a higher IP rating is essential. Remember that an exit filter should typically have a similar or higher IP rating to maintain the enclosure’s overall protection.

Corrosive Atmospheres: If your enclosure is in an area with corrosive gases or salt spray (like coastal or chemical plant environments), the materials of the fan housing, blades, and even the motor need to be resistant to corrosion. Standard steel or certain plastics might degrade quickly.

Choosing a fan unit with the appropriate IP rating and materials robust enough for your specific environmental challenges is key to its survival and continued performance.

How to Ensure the Selected Fan’s Dimensions and Mounting Style are Perfectly Compatible with My Electrical Enclosure?

This might seem like a basic step, but I’ve heard stories of perfectly specified fans arriving on-site only to not fit the enclosure. It’s a frustrating and entirely avoidable delay.

First, Overall Dimensions: Check the fan’s width, height, and especially its depth. [^1, 2] The depth is crucial because it determines how much space the fan will occupy inside (or outside) the enclosure. You need to ensure it doesn’t interfere with internal components, DIN rails, or door closure. Some fans, like certain Leipole models, offer a slim profile specifically to optimize space within the enclosure.

Cutout Dimensions: For panel-mounted fans (like most filter fans), the manufacturer will specify the exact size and shape of the cutout required in the enclosure wall or door. This needs to be precise. Ensure your enclosure can accommodate this cutout and that making it doesn’t compromise the enclosure’s structural integrity or other mounted components.

Mounting Style: Fans can be mounted in various ways:

- Panel Mount: Typically for filter fans, mounted through a cutout.

- DIN Rail Mount: Some smaller fans or fan controllers can be DIN rail mounted inside the enclosure.

- Roof Mount: Specific fan units are designed for top-mounting on enclosures, which can be beneficial for exhausting hot air that naturally rises.

- Internal Bracket Mount: Some fans might be designed to be mounted on internal brackets.

Verify that the fan’s intended mounting style is compatible with your enclosure design and your cooling strategy (e.g., where you want to bring air in and where you want to exhaust it). Also, consider the ease of installation and future maintenance. Can the filter be easily accessed and changed if you’re using a filter fan? For example, Leipole’s filter fans are designed with maintenance in mind.

Double-checking these physical compatibility aspects before ordering will save you a lot of headaches.

What are Some Common Mistakes to Avoid When Selecting an Enclosure Fan?

Over my years specializing in thermal management, I’ve seen a few common mistakes pop up repeatedly when people select enclosure fans. Avoiding these pitfalls can save you a lot of trouble, time, and money.

- Underestimating the Heat Load: Simply guessing the internal heat dissipation is a recipe for disaster. You need to sum up the heat output (in watts) of all components. If you miss something or use inaccurate figures, your fan will be undersized.

- Ignoring Static Pressure: This is a big one. As I mentioned, selecting a fan based only on its “free air” CFM rating without considering the resistance from filters and internal clutter will lead to much lower actual airflow and insufficient cooling. Always check the fan curve against your estimated static pressure.

- Incorrect Fan Type for the Application: Using an axial fan in a high-resistance environment or a centrifugal fan in a low-resistance, high-volume application means you’re not getting optimal performance or efficiency.

- Overlooking the Ambient Environment: Choosing a fan with an inadequate IP rating for a dusty or wet environment, or one not rated for the ambient temperature extremes, will lead to premature failure. The FKL55 series from Leipole, for instance, offers IP54/55 ratings suitable for many industrial environments.

- Forgetting about Voltage and Frequency Compatibility: Ordering a 230V AC fan for a 24V DC system (or vice-versa) is a costly and time-consuming error.

- Not Considering Noise: Especially in occupied areas, a fan that’s too loud can be a major issue. Check the dB rating.

- Poor Placement / Airflow Path: Even the best fan won’t work well if it’s placed incorrectly, or if the airflow path is blocked. Ensure cool air can reach the hot components and hot air has a clear exit path. Typically, you’d have an inlet filter fan low on the enclosure and an exhaust filter (often slightly larger) high on the opposite side.

- Neglecting Filter Maintenance: For filter fans, clogged filters drastically reduce airflow and increase static pressure, negating the fan’s effectiveness. Choose fans with easily replaceable filters, like the pleated filters in the FKL99 series which also offer lower resistance.

- Focusing Solely on Price: While budget is always a concern, the cheapest fan isn’t always the best value if it fails prematurely or doesn’t provide adequate cooling, leading to much higher costs from equipment damage or downtime.

By being aware of these common mistakes, you can make a more informed and effective fan selection.

Conclusion

Choosing the right enclosure fan is key to keeping your electrical cabinet “cool” and avoiding “heatstroke.” It ensures your valuable components operate reliably and last longer.