When designing an electrical cabinet, you must follow the design requirements in the system hardware connection manual to ensure that the cabinet can meet specific usage requirements. Among them, the fully sealed design is crucial, which can effectively protect the electronic components inside the cabinet from the influence of the external environment. At the same time, the temperature of the cabinet must be strictly controlled to ensure that it does not exceed the range allowed by the system unit, thereby ensuring the safe and stable operation of the cabinet.

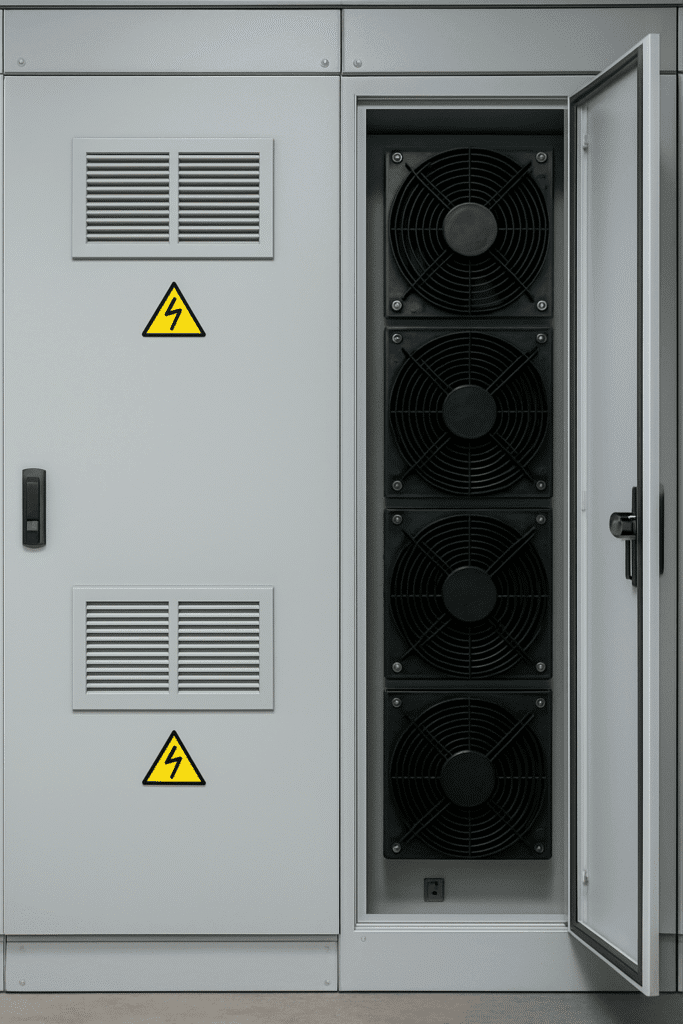

to use LEIPOLE’s cabinet fans and filters: The cabinet fans and filters provided by LEIPOLE, such asFK6621 fan filter and FK9922 fan filter, can effectively control the internal temperature of the cabinet, prevent electronic components from malfunctioning due to overheating or humid environment, and ensure stable operation of the system.

The principles of component division are:

● Group components with similar functions together;

● Reduce the number of connections between components as much as possible, and place control appliances with close wiring relationships in the same component;

● Separate strong and weak current controllers to reduce interference;

● For neatness and beauty, appliances with similar dimensions and weights can be grouped together;

● For the convenience of inspection and debugging of electrical control systems, components that require frequent adjustment, maintenance and are easily damaged can be grouped together.

When dividing the components of the electrical control cabinet, the connection methods between components, between electrical boxes, and between electrical boxes and controlled devices should be solved; the wiring methods between the various parts and components of the electrical control cabinet should generally follow the following principles:

● The input and output lines of the switchgear and control panel are generally connected with terminal blocks or wiring noses. Terminal blocks or wiring noses of different specifications can be selected according to the current size and the number of input and output lines;

● The electrical cabinets, control cabinets, cabinets (stations) and between them and the controlled equipment are connected with terminal blocks or industrial connectors;

● Various types of standard connectors should be used to connect weak current control components and printed circuit board components;

● The connection between components in the electrical cabinet, control cabinet, cabinet (station) can be directly connected by using the terminal blocks of the components themselves; the transition connection line should be connected with the terminal block transition connection, and the end should be processed with the terminal blocks of corresponding specifications.

LEIPOLE’s DIN rail terminal blocks and distribution blocks are designed for industrial control, supporting efficient and safe power distribution and wiring management, suitable for various current specification requirements.

| Transportation and environmental conditions | ||

| room temperature | Runing time | 0℃~45℃ |

| During storage or transportation | -20℃~60℃ | |

| relative humidity | usually | <75% |

| Short term ( a month) | <95% | |

| Vibration | Runing time | <0.5G |

| Non runtime | <1G | |

| Altitude | Runing time | <1000m |

| Non runtime | <1200m | |

| environment | Typical workshop environment | |

LEIPOLE’s cabinet lighting and grounding busbar provide reliable internal support for electrical cabinets, ensuring that equipment can still operate safely in complex environments.

Electrical control devices usually require the production of separate electrical control cabinets and boxes. The following aspects need to be considered in their design:

● Determine the overall size and structural type of the electrical box and cabinet according to the operation requirements and the size of various electrical components in the control panel, box, and cabinet. Unless in special circumstances, the overall size of the electrical control cabinet should be consistent with the basic size and series of the structure;

● Design the mounting bracket in the box according to the overall size, structural type, and installation size of the electrical control cabinet, and mark the size of the mounting holes, mounting bolts, and grounding bolts, and indicate the matching method. The materials of the cabinet and box should generally be special profiles for the cabinet and box;

● Design the door opening method and type of the electrical control cabinet according to the requirements of the on-site installation location, operation, and maintenance convenience;

● In order to facilitate the ventilation and heat dissipation of the electrical appliances in the control cabinet, design ventilation holes or ventilation slots at appropriate parts of the box body, and if necessary, design forced ventilation devices and ventilation holes on the upper part of the cabinet body;

● In order to facilitate the transportation of the electrical control cabinet, a suitable lifting hook should be designed or movable wheels should be designed at the bottom of the box body.

LEIPOLE provides comprehensive solutions for electrical cabinet accessories: from cable entry plates to cable waterproof connectors, LEIPOLE’s products cover a wide range and provide all-round support for the design and operation of electrical cabinets. Please contact online customer service to learn more.