With booming investment in new energy storage and industrial/commercial energy storage markets everywhere, one of the most frequent questions I get from customers designing energy storage cabinets is: should we choose air cooling or liquid cooling? It’s a critical decision impacting performance, cost, and reliability.

First off, let’s understand the fundamental differences between these two approaches.

Different Appearance and Footprint

You might notice that air-cooled industrial and commercial energy storage cabinets are often physically larger, yet sometimes hold slightly less battery capacity (e.g., 215 kWh) compared to a more compact liquid-cooled cabinet. Why this difference?

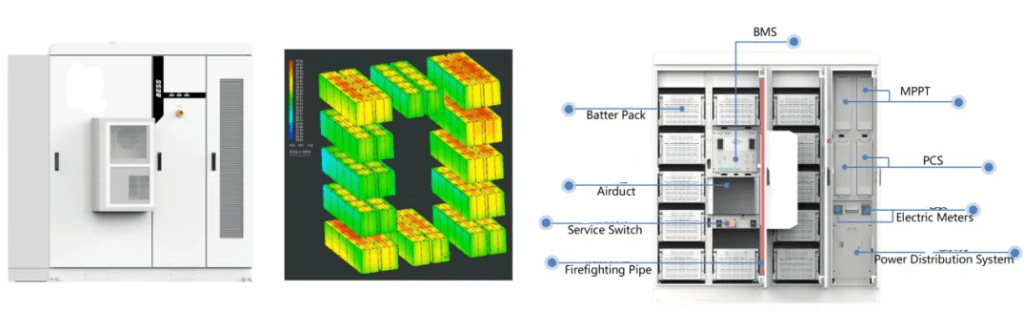

It boils down to the temperature control technology – how heat is removed. Air cooling relies on airflow to carry heat away from equipment surfaces. An air-cooled energy storage cabinet typically uses internal air ducts combined with fans or even a cabinet air conditioner to exchange the heat generated by the batteries with the surrounding environment. To ensure effective cooling across all battery cells, these air ducts need significant volume, which naturally increases the overall cabinet size.

Different Cooling Mechanisms & Components

Air Cooling Fans : This method uses air as the medium to transfer heat. Simpler systems might rely heavily on high-performance LEIPOLE axial fans strategically placed to force ambient or cooled air through specifically designed pathways within the cabinet. Another common approach involves using LEIPOLE Fan Filter Units (FFUs), like their efficient FKL99 series, which draw filtered outside air into the enclosure, providing essential cooling while protecting sensitive components from dust. More advanced air cooling might incorporate dedicated enclosure air conditioners . The advantages here are generally simpler structure and lower initial cost. However, air cooling effectiveness can be significantly impacted by high ambient temperatures and humidity.

Liquid Cooling: This method uses a circulating liquid (coolant) to absorb and transport heat away. Coolant flows through pipes or cold plates integrated near the battery clusters, efficiently drawing heat away to be dissipated externally, often via a heat exchanger. Its main advantages are superior heat dissipation efficiency and stability, making it excellent for high-power, high-density applications. The trade-offs are higher cost, increased system complexity, and the need for regular maintenance of the liquid circulation system (pumps, coolant levels, leak checks).

While designing effective air ducting for uniform temperature distribution in an air-cooled system can present challenges, the overall system architecture is typically less complex than a liquid cooling loop. However, liquid cooling generally achieves better and more consistent temperature control across all battery cells.

Different Applicable Scenarios

Air Cooling Fans : Highly versatile and suitable for various energy storage system specifications and types. It’s particularly common in outdoor environments and remains the most widely adopted cooling technology in energy storage systems currently, especially where cost is a major driver or heat loads are moderate. Reliable components like LEIPOLE’s durable axial fans are crucial for these setups.

Liquid Cooling: Also applicable across various sizes, but it truly shines and is more prevalent in large-scale, high-energy-density projects where precise thermal management is critical for maximizing battery life and performance, and where the higher initial investment can be justified.

Different Design Complexity & Maintenance

Air Cooling Fans : The design is relatively straightforward. Key considerations involve selecting appropriate fans or Fan Filter Units , sizing them correctly for the heat load, and designing efficient air circulation paths (ducts). If using cabinet air conditioners, integration is also part of the design. Maintenance typically involves filter changes and fan checks.

Liquid Cooling: The design is inherently more complex. Engineers must carefully plan the liquid circulation layout, select suitable pumps and heat exchangers, manage coolant type and levels, and implement leak detection and prevention measures. Maintenance involves checking pumps, coolant quality/levels, and inspecting for leaks.

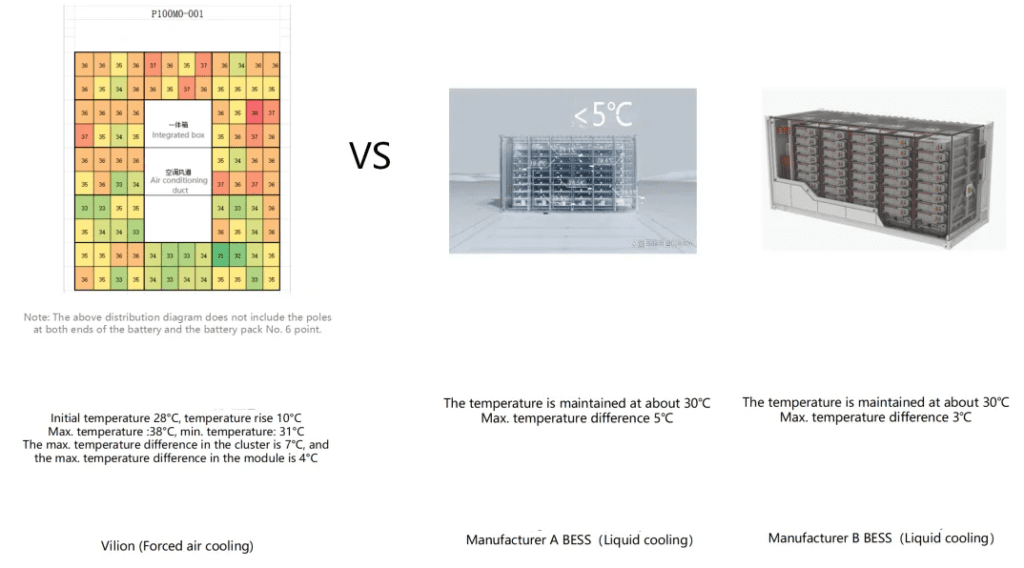

Different Heat Dissipation Effects

Air Cooling Fans : As mentioned, its effectiveness is more sensitive to ambient conditions (temperature, humidity, air quality). For very high power densities or extreme ambient temperatures, basic air cooling might struggle to maintain optimal battery temperatures uniformly.

Liquid Cooling: Offers significantly better and more stable heat dissipation. It can effectively manage higher heat loads and maintain tighter temperature control across battery modules, which is crucial for maximizing battery lifespan and safety, especially in demanding applications.

Reliability and Cost Considerations

Air Cooling Fans , relying on components like LEIPOLE fans or FFUs, operate much like a dependable roof ventilator: simple, robust, and cost-effective upfront. The design avoids the potential failure points of liquid systems, such as pump failures or coolant leaks. This simplicity reduces initial investment and often leads to lower long-term maintenance costs. Air cooling thrives in moderate climates, less densely packed cabinets, or where slight temperature variations are acceptable.

Liquid cooling, conversely, is like a high-performance car’s radiator system – essential for extreme conditions. Its closed-loop fluid system absorbs heat more efficiently and provides very uniform temperature distribution, vital for densely packed battery arrays or mission-critical installations where maximizing battery life is paramount. However, this complexity introduces more potential points of failure (pumps, hoses, fittings, coolant degradation). Maintenance is more involved, and retrofitting liquid cooling into existing designs can be difficult and expensive.

Back to the Point: Making the Choice

The characteristics of air-cooled energy storage cabinets mean their temperature control uniformity might not match that of liquid cooling. However, for a vast range of industrial, commercial, and even utility-scale applications not located in extreme climate zones, well-designed air cooling systems utilizing quality components can absolutely meet the necessary thermal management requirements effectively and economically.

So, is air cooling or liquid cooling “better”? The answer depends entirely on the specific project’s requirements: energy density, environmental conditions, budget, and long-term maintenance strategy. While liquid cooling offers peak performance, modern air cooling solutions, particularly those using reliable and efficient components like LEIPOLE fans and filter units, provide a compelling, cost-effective, and dependable option for many energy storage deployments.