Machinery

Extend The Lifespan: LEIPOLE Cooling Solution Maximize the Machine life by 60%

Metalworking dust strikes!

Dust filter failure rate is reduced to zero

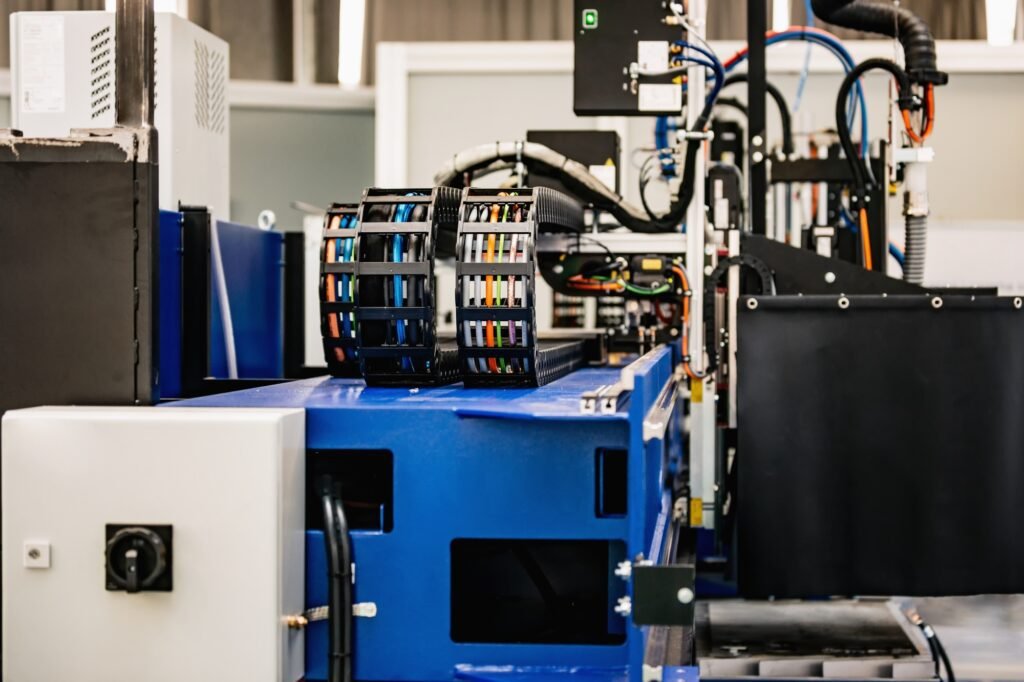

The machinery industry forms the backbone of modern manufacturing, enabling efficient production processes through automation, precision control, and robust equipment design. From traditional machine tools to cutting-edge robotics and Industry 4.0 smart factories, machinery applications face unique challenges that require specialized electrical and thermal solutions.

Modern machinery systems consist of numerous interconnected components such as motors, drives, controllers, sensors, and human-machine interfaces. These critical elements require reliable protection from environmental factors while maintaining optimal operating conditions for sensitive electronic equipment.

Application areas and challenges

Metal cutting machine tools (CNC machine tools, machining centers, lathes, milling machine control cabinets):

Metal cutting machine tools are core equipment for mechanical manufacturing and are used for the processing of precision parts. They have high requirements for electrical system performance, are temperature sensitive, have severe electromagnetic interference, and are sensitive to voltage fluctuations.

Coolant environment: Coolant is used during machine tool processing, and the control cabinet may be splashed and corroded by coolant, requiring electrical components to have a certain degree of corrosion resistance and protection level.

Vibration and shock: Vibration and shock will occur during machine tool processing, requiring electrical components to have good vibration and shock resistance.

Industrial robots (welding robots, handling robots, spraying robot control cabinets):

Industrial robots are important tools for realizing production automation and are widely used in various industrial scenarios. They have high requirements for electrical system flexibility and reliability. The control cabinet has high heat dissipation requirements, limited space, complex cable wiring, and reliable connection requirements in vibration environments.

Movement flexibility: The robot needs to move flexibly, the control cabinet and electrical components need to adapt to the robot’s range of motion and working posture, and the cable wiring needs to ensure freedom of movement.

Fast response and high-precision control: Robots need to respond quickly to control instructions and achieve high-precision motion control, and have high requirements for the response speed and control accuracy of the electrical system.

Automated production line/assembly line (assembly line control cabinet, conveying equipment control cabinet):

Automated production line is the key to achieving large-scale and high-efficiency production. It is widely used in automobile, electronics, food and beverage, medicine and other industries, and has high requirements for electrical system stability and efficiency.

Synchronous and coordinated control: Automated production line requires multiple devices to work together, and the electrical control system needs to achieve precise synchronization and coordinated control to ensure the smooth operation of the production line.

High-speed and efficient operation: Automated production line pursues high-speed and efficient production, and the electrical system needs to adapt to the requirements of high-speed operation and frequent start and stop.

Construction machinery (excavator, loader, crane control cabinet):

Construction machinery is widely used in construction, mining, transportation and other fields. The working environment is harsh and the durability and reliability of the electrical system are extremely high.

Facing extremely harsh environments: Construction machinery usually works in extremely harsh environments, such as high temperature, severe cold, dust, muddy water, strong vibration, strong impact, etc., which puts extreme requirements on the durability and reliability of electrical components.

High-intensity and long-term operation: Construction machinery usually needs to operate for a long time and at a high intensity. The electrical system needs to withstand high loads and have good heat dissipation performance.

Difficult maintenance and large downtime losses: The maintenance space of construction machinery is limited and difficult. Once it is down, the economic losses caused are huge, requiring electrical components to have extremely high reliability and maintenance-free characteristics.

Extremely high safety requirements: The operating environment of construction machinery is complex and the safety risks are high. The safety of the electrical system is the key to ensuring the safety of operators and equipment.

Factors and challenges affecting the development of the machinery manufacturing industry:

Technology innovation drive: The machinery manufacturing industry relies on technological innovation to drive development. New technologies, new processes and new materials continue to emerge, driving product upgrades.

Increasing demand for personalized customization: The market demand for personalized and customized products continues to increase, and machinery manufacturing companies need to provide more flexible and customized solutions.

Intensified global competition: Global competition in the machinery manufacturing industry is becoming increasingly fierce. Companies need to continuously improve product quality, reduce costs and improve service levels in order to remain invincible in the competition.

Risks in the supply chain of the industrial chain: The global supply chain of the industrial chain is facing a reshaping, and machinery manufacturing companies need to strengthen supply chain management and reduce supply chain risks.

Sustainable development pressure: The global requirements for environmental protection and sustainable development are increasing, and the machinery manufacturing industry needs to develop in the direction of greening and low carbonization.

LEIPOLE SOLUTIONS FOR MACHINERY

LEIPOLE solutions increase efficiency, reliability, and longevity across industrial automation applications worldwide. Our comprehensive range of thermal management, electrical connection, and power transformation products ensures optimal protection for critical systems in challenging environments.

Contact our engineering team today to discuss your specific requirements and discover how LEIPOLE’s industrial automation solutions can enhance your operational performance.