As the intermediate link between outdoor electrical equipment and indoor measurement, control, protection, communication and other equipment, outdoor electrical cabinets play an extremely critical role. The stability of their work will directly affect the safe operation of the power grid. However, they also have a “common problem” – due to long-term outdoor operation, exposure to wind, sun, rain, and a relatively harsh working environment, there are often problems such as water leakage in the cabinet, loose cable entry plugging, and non-standard plugging.

1. Understand the condensation problem

·What is condensation phenomenon?

Condensation is a phenomenon in which water vapor in the air condenses into liquid water when it encounters a cold surface below the dew point temperature. This phenomenon is particularly common in outdoor electrical enclosures, especially in environments with large temperature changes.

·Why are outdoor cabinets prone to condensation?

Environmental impact: The outdoor electrical enclosure is directly exposed to the natural environment, and the temperature difference between day and night is significant.

Internal heat source: The heat generated by the operation of the equipment comes into contact with the outside cold air, forming a temperature difference.

High humidity: High humidity in the air provides a sufficient source of moisture for condensation.

Effects of condensation on electrical equipment

Corrosion risk: Condensation can cause metal parts to rust, reducing the structural strength and electrical conductivity of the equipment.

Induced short circuit: Moisture may cause short circuits in electrical components, seriously affecting the safety of the equipment.

Shortened equipment life: Long-term condensation problems will accelerate component aging and increase maintenance costs.

2. Key factors in the formation of condensation

Ambient temperature changes: When the temperature difference between day and night is large, the cooled metal surface can easily reach the dew point temperature, causing condensation.

Humidity level: The higher the humidity in the air, the greater the likelihood of condensation forming.

Temperature difference between inside and outside the cabinet: The equipment generates heat during operation. When the internal temperature is higher than the external temperature, the condensation phenomenon will be more obvious.

Impact of sealing: Cabinets with insufficient sealing can easily allow moisture to penetrate, exacerbating condensation problems.

Ventilation conditions: Poor ventilation can lead to moisture accumulation and increase the risk of condensation.

3. Anti-condensation solutions

A. Active protective measures

·Heater application

PTC Heater: Utilizes positive temperature coefficient (PTC) materials to automatically adjust temperature to prevent condensation.

Fan heater: The LEIPOLE fan heater distributes heat evenly and prevents excessive cooling of local areas.

Intelligent temperature control system: Automatically adjusts heater operation according to changes in temperature and humidity, saving energy and efficiency.

Refrigeration system selection

Suitable cooling capacity: Choose an appropriate refrigeration system based on cabinet size and equipment heat requirements to avoid overcooling.

Coating water management: Coating waterproof materials on the surface to reduce the adhesion of condensation water.

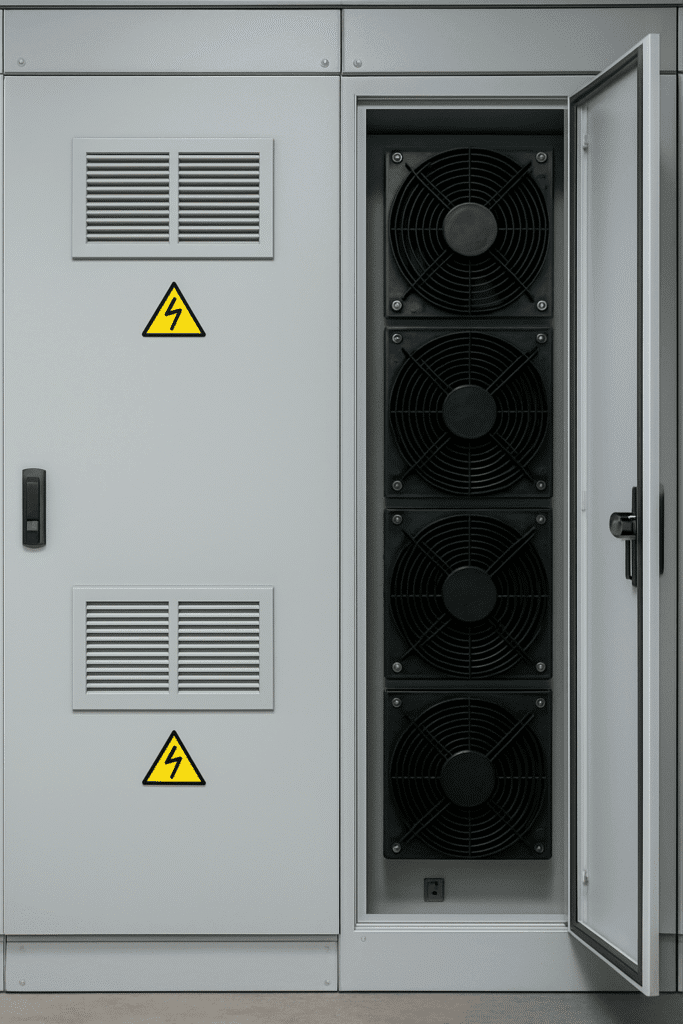

·Ventilation system design

Ventilation: Optimizes air flow and reduces moisture build-up.

Filter selection: Choose LEIPOLE FKL series ventilation window high-efficiency filters to prevent moisture and dust from entering.

B. Passive protective measures

·Sealing system optimization

Improve the quality of sealing strips to ensure tightness.

Material selection considerations

Use corrosion-resistant materials, such as stainless steel or galvanized steel, to extend equipment life.

Protection level ensured

Make sure the enclosure is IP65 or higher to prevent water vapor intrusion.

Drainage design

Set up drainage holes or water guide structures to drain condensed water in time.

4. Monitoring and Control Strategy

Humidity adjustment solution

Install a humidity sensor to monitor the humidity level in the cabinet in real time.

Intelligent control system

Use an integrated temperature and humidity control system to automatically adjust equipment operation according to environmental conditions.

Alarm function settings

Set humidity and temperature alarms to remind maintenance personnel in time.

Remote monitoring options

Realize remote monitoring and optimize maintenance efficiency through Internet of Things (IoT) technology.

5. Preventive maintenance recommendations

Regular inspection items

Check the operation of seals, ventilation filters and heating equipment.

Maintenance cycle recommendations

Develop a quarterly or annual maintenance schedule based on environmental conditions and frequency of equipment use.

Maintenance of key components

Regularly replace aging seals and clean filters to ensure normal operation of the equipment. Bar

Countermeasures

In seasons where condensation is prone to occur, increase the frequency of inspections and take measures in advance.